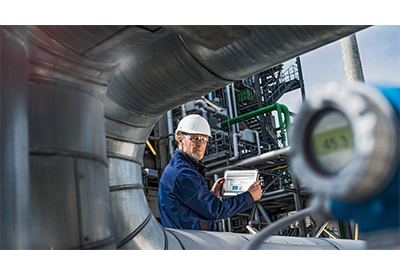

Endress+Hauser Prosonic G Flowmeters Redefine Process Gas Measurement

March 5, 2020

The new, exceptionally robust Endress+Hauser Proline Prosonic Flow G 300/500 flowmeters with optional integrated pressure and temperature sensors provide highly accurate, real-time values in even the most demanding environments. The Prosonic Flow G measures both dry and wet gases – natural gas, process gas or gas mixtures, either offshore or onshore – using ultrasonic flow measuring technology that has proven its reliability in decades of experience in the oil and gas as well as chemical industries.

The Prosonic Flow G technology ensures precise measured values (±0.5%) with unmatched repeatability, even when process and ambient conditions fluctuate significantly. These flowmeters deliver this high accuracy in process temperatures up to 150 °C (302 °F) and pressures up to 1450 psi. Their robust construction with high grade stainless steel for all wetted parts and the entire sensor body assures very high corrosion resistance for long life operation without maintenance, saving both time and money. Their innovative sensor concept is equipped with a special drainage system that immediately dissipates any condensate forming in the sensor pocket area, assuring reliable measurement without any degradation of signal quality.

Combining these attributes with the extensive functionality of the Proline 300/500 transmitters creates new options for process control and monitoring. When ordered with built-in temperature and pressure sensors, the input from these sensors can be combined with the measured sound velocity to calculate a great number of additional gas properties important for process control. For example, the Prosonic Flow G 300/500 can be supplied with an “Extended Gas Analysis” function package, e.g. for special applications or for increased process control requirements. Depending on the selected gas type, this enables the calculation of additional parameters and process variables like volume flow, corrected volume flow, mass flow, energy flow and much more.

Prosonic Flow G flowmeters can be combined with two different Proline transmitters: as a compact version (with Proline 300) or as a remote version (with Proline 500) with up to four inputs and outputs.

For more information, visit www.ca.endress.com.