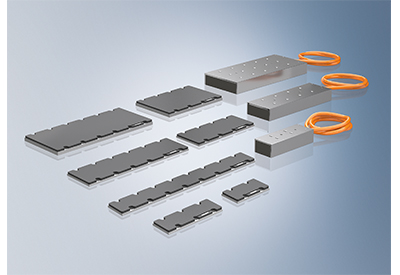

Beckhoff: Highly Dynamic AL8000 Linear Motors Provide Flexible, Modular Design

November 2, 2020

Backed by its wealth of expertise in the development of rotary servomotors, Beckhoff has added an innovative product to its portfolio in the area of drive technology. The AL8000 series, a new generation of high‐performance and modular linear motors, was developed in cooperation with Fertig Motors, the dynamically growing Beckhoff subsidiary.

The new AL8000 product family is based on a modular system design consisting of linear motors and magnetic plates. Users can choose between three widths: 50 mm (AL8x2x), 80 mm (AL8x4x) and 130 mm (AL8x6x). In addition, each width category offers a broad range of different linear motor types in terms of overall length, type of winding and cooling type. The standard product portfolio therefore contains a total of 28 different linear motor types for implementing highly dynamic and powerful linear axes to suit specific application requirements. Depending on the size of the linear motor, peak forces of 120 to 6,750 N are possible as well as maximum speeds of up to 12 m/s.

Like the established AM8000 rotary servomotors, Beckhoff fully developed and manufactured the AL8000 family of linear motors in Germany. A consistently high level of production quality is therefore guaranteed as well as high availability and short supply chains for realizing durable and highly reliable applications with linear motor technology. Further advantages include outstanding service and support, ensuring fast and flexible fulfillment of customer requirements.

Modular coil design

In keeping with the modular system principle, the entire linear motor coil part is composed of identical individual segments. This construction is especially favorable from a production perspective: Depending on which linear motor is ordered, the production process can be adapted quickly and easily to accommodate the relevant number of segments.

Another advantage is the precisely symmetrical structure of the linear motors. There are uniform intervals between the mounting holes of the linear motors throughout the entire AL8000 series. This makes it easier for machine builders to construct the machine slide and ensures consistent force and temperature distribution within the motor without critical hot spots.

For more information, visit www.beckhoffautomation.com.