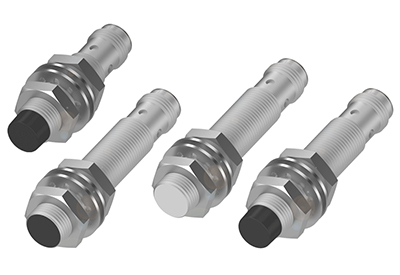

Balluff’s Inductive Factor 1 Sensors Detect Ferrous and Non-ferrous Metals Reliably at the Same Rated Switching Distance

July 29, 2019

Balluff’s new generation of high-precision inductive factor 1 sensors accurately detect ferrous (iron-based) metals like steel and non-ferrous metals like aluminum and brass at the same rated switching distance. Typical inductive sensors have a reduced range for non-ferrous metal, requiring a correcting factor to calculate their switching distance. Not so with Factor 1 sensors; they detect both types of metal with no correction factor needed.

These inductive factor 1 sensors keep operating in harsh environments. They are magnetic-field resistant, so their function is not disturbed by strong electromagnetic fields, which are often found in welding applications. A PTFE coating on the housing helps keep weld spatter from sticking to the sensor.

Balluff has engineered this new generation of sensors with an IP68 rating and extended the working ambient temperature range to –40 to +85 °C. Add their improved housing and they are a clear improvement over the previous IP67-rated generation of devices.

Key features include:

- Inductive Factor 1 sensors accurately detect all metals (ferrous and non-ferrous) at the same rated switching distance

- Magnetic-field resistant and PTFE-coated housing performs in harsh environments, is resistant to weld spatter

- IP68 rated, with extended ambient temperature range from –40 to +85 °C, both improved from previous generation

- Ceramic coated sensing face material (for BES05KU version) provides further weld spatter resistance

- Well suited for metalworking applications, including mobility tier 1, OEM, and stamping

Learn more at: www.balluff.com