AutomationDirect: NEMA Stepper Motors – Single-Shaft and Dual-Shaft

July 15, 2021

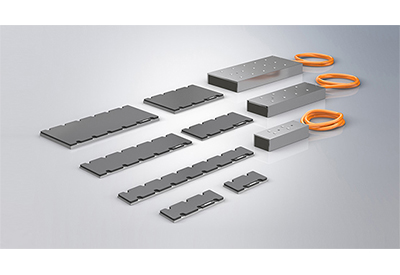

SureStep high-torque stepping motors are designed to handle a wide range of automation applications such as woodworking, assembly, and test machines.

- Motors are available in both single-shaft and dual-shaft configurations.

- These square frame or “high-torque” style stepping motors are the latest in bipolar technology, resulting in the best torque to volume ratio.

- NEMA 14, 17, 23, 34 and 42 mounting flanges

- Holding torque ranges from 8 to 4532 oz-in.

- Optional 6, 10, or 20-foot extension cables with locking connectors interface any of the stepping motors to the microstepping drive.

- Extension cables can be easily cut to length, if desired.

- Position feedback encoder included in integrated motor / drives and separate motors with an “E” part number.

- Encoder adapter plate available (only necessary for mounting encoders to NEMA 42 motors)

Motor Features

- Square frame step motor style produces high torque

- 2-phase bipolar, 4-lead

- Available in single-shaft and dual-shaft models

- 1.8° per step, 200 Steps per Revolution

- Standard NEMA Sizes (14, 17, 23, 34 and 42)

- NEMA 42 frame size … New!

- CE Compliant