Slotted vs Slotless Brushless DC Motors | Key Differences and Applications

November 14, 2025

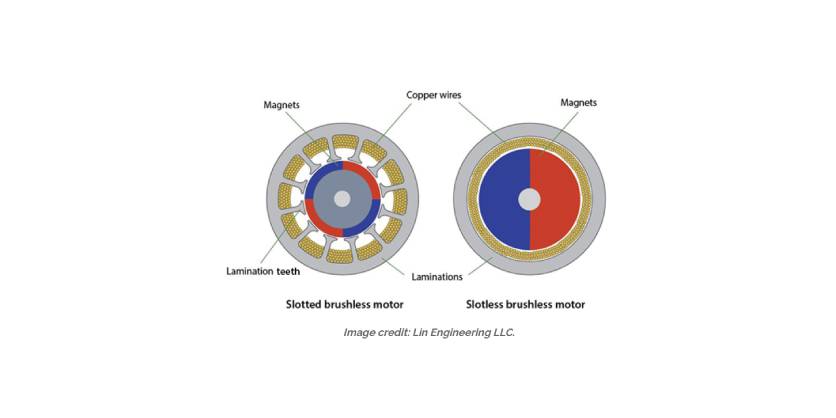

In brushless DC motor design, the geometry of the stator and rotor directly determines how torque, efficiency, and smoothness are achieved.

Two of the most common configurations are slotted and slotless brushless DC motors. Both are widely used in precision motion control, robotics, and mechatronic systems, but they differ substantially in electromagnetic behavior and application suitability.

Understanding these differences is essential for selecting the correct brushless motor for your design.

Construction Overview

| Feature | Slotted Brushless Motor | Slotless Brushless Motor |

|---|---|---|

| Stator Design | Copper coils wound into iron slots formed by laminated steel teeth | Coils wound around a smooth, ironless stator bore—no slots or teeth |

| Rotor | Permanent magnets attached to the rotor | Same—rotor with permanent magnets |

| Air Gap | Small air gap increases magnetic flux density | Larger air gap reduces flux density slightly but improves smoothness |

| Winding Arrangement | Concentrated windings around individual teeth | Distributed or self-supporting windings across the full stator circumference |

| Magnetic Coupling | Strong, focused magnetic field | Weaker but more uniform magnetic field |

| Cogging Torque | Present due to interaction between magnets and teeth | Absent—no preferred rotor positions |

| Torque Density | High | Moderate |

| Noise and Vibration | Higher | Very low |

| Motion Smoothness | Moderate | Excellent |

| Manufacturing Complexity | Lower | Higher (requires precision coil forming and placement) |

Electromagnetic Design

Slotted and slotless brushless motors share the same operating principle—a rotating magnetic field interacts with permanent magnets on the rotor to generate torque. The difference lies in how the stator influences the field:

- Slotted Motors: The stator teeth concentrate magnetic flux through the coils. This yields a stronger coupling between stator and rotor, resulting in higher torque density. However, it introduces cogging torque—a detent-like effect caused by the rotor magnets aligning with the stator teeth. Cogging leads to torque ripple and less uniform rotation, especially at low speeds.

- Slotless Motors: By removing stator teeth, the air gap becomes uniform and the field more evenly distributed. The absence of cogging torque ensures smooth, continuous motion ideal for precision applications. The trade-off is a slight reduction in flux density and torque per ampere due to the increased air gap.

Rotor and Air Gap Effects

Both brushless motor types use rotors with permanent magnets, but how those magnets interact with the stator differs significantly:

- In slotted motors, the smaller air gap allows stronger flux linkage and higher peak torque but increases iron losses and magnetic attraction forces.

- In slotless motors, the larger air gap reduces flux density but also minimizes iron losses, hysteresis, and acoustic noise. This configuration supports higher operating speeds and smoother dynamic control.

The rotor’s moment of inertia is typically lower in slotless motors, improving acceleration and deceleration response in servo systems.

Thermal and Mechanical Behavior

Heat dissipation also varies between the two architectures:

- Slotted designs embed windings within the iron core, allowing better thermal conduction to the housing. They sustain higher continuous current levels and are preferred where thermal loading is heavy.

- Slotless designs have windings closer to the air gap, reducing heat transfer efficiency but improving dynamic balance. They are often used in lightweight, high-speed, or low-inertia systems where rapid motion changes are critical.

Noise, Vibration, and Motion Smoothness

The periodic magnetic forces in slotted motors produce audible noise and vibration, especially under variable-speed operation. Slotless motors, with no magnetic detent positions, deliver ultra-smooth, near-silent rotation. This characteristic is essential in medical instruments, imaging systems, and gimbal drives where mechanical stability directly affects output quality.

Efficiency and High-Speed Operation

Efficiency depends on both magnetic and mechanical losses:

- Slotted motors exhibit higher torque per volume but greater iron and eddy-current losses at high RPM.

- Slotless motors achieve superior high-speed efficiency because the smoother field distribution minimizes core losses. They are frequently used in applications exceeding 50,000 rpm, including centrifuges, dental turbines, and microdrives.

Torque Characteristics and Control Precision

The torque–current relationship differs between the two designs:

- Slotted motors produce higher maximum and holding torque. The discrete teeth help generate stable torque at low speeds, beneficial for industrial automation or actuation systems.

- Slotless motors provide a linear torque–current curve with minimal ripple, allowing fine motion control in servo loops and robotic joints requiring precise micro-positioning.

Manufacturing and Cost Factors

Manufacturing complexity affects cost and scalability:

- Brushless slotted motors use standard lamination stacks and automated winding techniques, making them cost-effective for large production runs.

- Brushless slotless motors require precision winding and assembly to maintain the uniform air gap. Their higher cost is offset by performance advantages in premium motion systems.

Application Suitability

| Application Category | Preferred Motor Type | Rationale |

|---|---|---|

| Industrial drives and automation | Slotted | High torque density, durable, good heat dissipation |

| Power tools and actuation systems | Slotted | Strong magnetic coupling and high load capability |

| Robotics and collaborative automation | Slotless | Smooth, quiet motion, no cogging |

| Medical and dental devices | Slotless | Precision control, low vibration, high-speed efficiency |

| Aerospace gimbals and stabilization | Slotless | Lightweight, low inertia, silent operation |

| Conveyor or pump systems | Slotted | High torque and continuous-duty performance |

| Laboratory instruments and optical systems | Slotless | Zero cogging and high positional accuracy |

Both slotted and slotless brushless DC motors have distinct advantages:

- Slotted Motors: Compact, torque-dense, and thermally efficient, but with cogging and higher vibration. Best suited for torque-intensive, industrial, or cost-sensitive environments.

- Slotless Motors: Smooth, quiet, and cog-free operation with excellent dynamic response. Best for precision, low-vibration, or high-speed applications where smoothness outweighs raw torque.

Selecting the right motor depends on whether your priority is power output and cost, or precision and smoothness.

Related Story

Electromate Recognized as a 2025 Recipient of the Canadian Business Excellence Awards for Private Businesses

Electromate Inc. is proud to announce it has been named a recipient of the 2025 Canadian Business Excellence Award for Private Businesses by Excellence Canada. This prestigious designation recognizes Canadian businesses that demonstrate a strategic approach to improving business performance and achieving a sustained culture of excellence.

Now in its ninth year, the Canadian Business Excellence Awards for Private Businesses celebrates organizations across Canada that clearly demonstrate excellence in three key performance areas: Delighted Customers, Engaged Employees, and Innovation.