Eye Surgery with Valve Technology

February 19, 2019

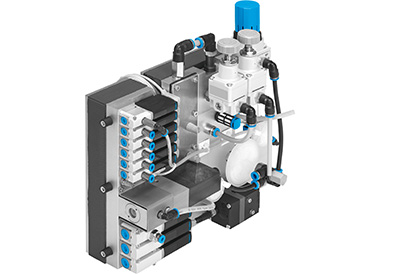

State-of-the-art pneumatic technology is not just for industry. It plays a much wider role improving our lives. For example, advances in cataract surgery are getting an assist from Festo piezo, proportional and fast-switching valves performing critical functions in state-of-the-art surgical workstations like the QUBE and QUBE Pro from Germany’s BYTEC.

These workstations are the technical assistants of choice for many eye surgeons performing cataract and retina surgery. Their pneumatic control unit consists of solenoid and piezo valves that drive cutting tools, vacuum-assisted suction removal and delivery of liquids. Piezo technology like Festo’s VEAB valve regulates the pressure in the system with unerring accuracy while fast-switching valves increase the cutting rates for precise incisions and suctioning.

During cataract surgery, the opacified lens is broken up by an ultrasound probe. A high-precision suction/rinsing device, which is actuated by proportional valve MPYE from Festo, removes the lens fragments. The required infusion pressure is controlled by a VEAB valve. After the residual tissue has been rinsed and removed, the surgeon inserts the new artificial, clear lens. High-precision pressure regulation is also used during surgery on the anterior segment of the eye (vitrectomy).

Piezo valves like VEAB offer several notable benefits: They are lightweight, quiet and accurate with minimal heat generation and are practically wear-free. Even so, in these surgical work stations, redundant valves are included for each valve function to ensure the highest level of safety.