Why Stop at Efficiency? Build EtherCAT Networks for Maximum Reliability

September 16, 2025

In the race toward smarter, more automated industrial operations, every microsecond counts. In response to rising demands for higher precision, speed, and synchronization across industries like robotics, packaging, and semiconductors, EtherCAT has become the standard for high-performance motion control. Its unique “on-the-fly” processing principle delivers deterministic, high-speed communication that traditional industrial Ethernet protocols simply cannot deliver.

But you probably know all of this already. These benefits are likely the reason you may have been using EtherCAT for your critical applications to begin with. But as industrial systems become more complex, a hidden vulnerability in the most common network topology could be threatening your operations.

The Weak Link in the Chain

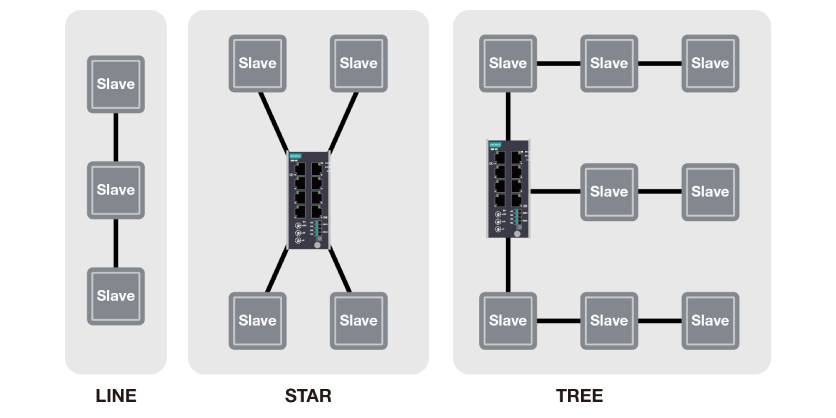

For simplicity and cost-effectiveness, many EtherCAT networks are deployed in a daisy-chain (or line) topology. In this setup, several devices are connected to each other in a simple, linear chain. Despite the benefits, this design has a critical single point of failure.

Think of it like a series of connected extension cords: if you unplug one of the cords, the others behind it also lose power. In an industrial environment, many things can happen. A node in the chain fails, a damaged cable, or a lost connection somewhere in the chain. If that happens, every downstream device in the chain immediately loses its connection to the master. This can disrupt an entire section of your production line, causing productivity loss, costly downtime, and complex troubleshooting. The more devices you add to the chain, the higher the risk of something like this happening.

From a Fragile Chain to a Resilient Network Architecture

So, how can you still take full advantage of EtherCAT technology without being chained to its simplest, most fragile topology? The answer lies in building more resilient network structures using different topologies. EtherCAT supports several topologies, including tree and star. This article examines how these topologies help build more robust EtherCAT networks.

Instead of a single line, a tree topology uses EtherCAT junctions as branching points. The master connects to a junction, which then provides multiple branching ports. Each of these ports can connect to an individual slave device or, more commonly, to its own smaller daisy-chain segment (a branch). This creates a tree-like structure, with the master as the root, junctions as the main limbs, and device segments as the smaller branches. By comparison, a star topology is a simpler version of a tree topology—it’s a tree with only one level of branching. If a device or cable failure happens in one branch, the other branches are not affected. This flexible topology design offers three immediate advantages:

- Fault isolation: Failures are contained within a single segment, preventing catastrophic, topology-wide shutdowns.

- Simplified troubleshooting: Technicians can quickly identify the exact segment where the fault occurred, drastically reducing the mean time to repair (MTTR).

- Flexible expansion: Topologies can be further branched out with new devices or entire machine modules without disrupting the existing network.

Industry Challenges

Let’s look at two real-world applications: semiconductor and lithium-ion battery manufacturing. Both applications use EtherCAT to achieve real-time motion control and precise production. Sensitive applications like these have no tolerance for system downtime and require reliable connections to sustain seamless EtherCAT communication.

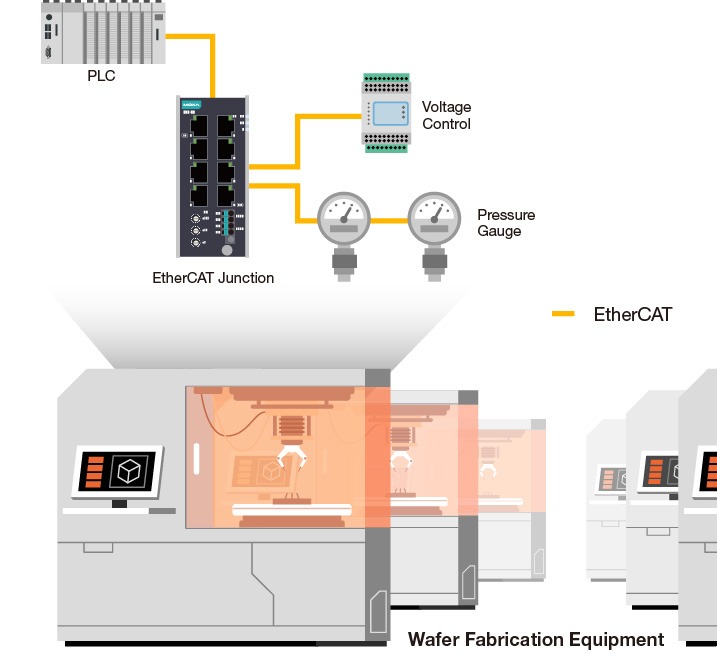

Semiconductor Equipment Manufacturing

In semiconductor manufacturing, the EtherCAT protocol is becoming the mainstream technology. Taking PECVD equipment as an example, it is often challenging to add new devices in space-constrained and noisy environments. The equipment needs to connect multiple sensors, pressure gauges, and power controls. To do that, machine builders need compact EtherCAT products with multiple ports that are resistant to interference while also factoring in future expansion capabilities.

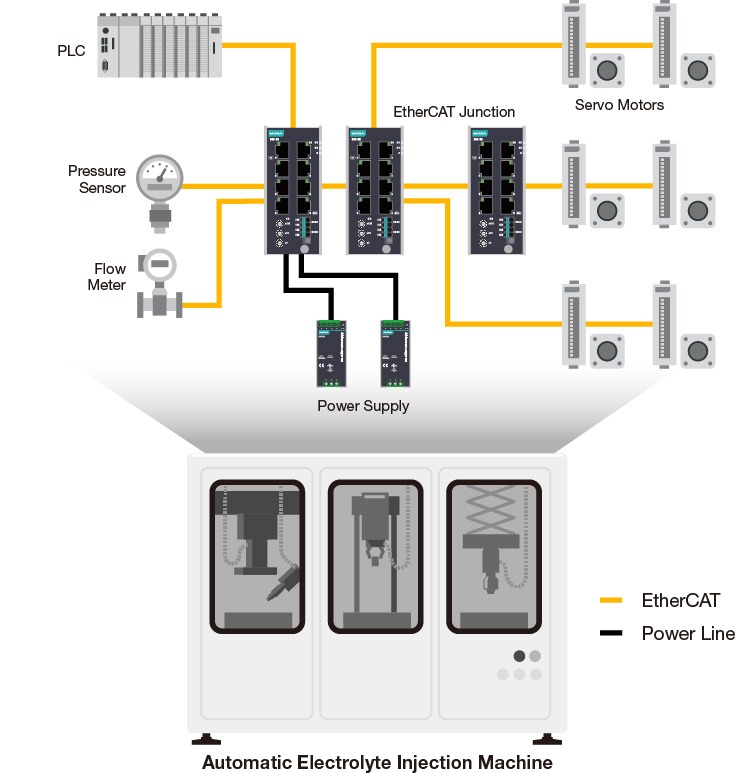

It’s not uncommon for lithium-ion battery manufacturing equipment to divide several hundred EtherCAT slave devices into multiple network segments. At the same time, the manufacturer needs to make sure operations keep working normally during power interruptions or system instability. Since manufacturers often use EtherCAT devices from different providers, interoperability is another major concern. It’s therefore important to evaluate and choose EtherCAT devices that have been tested for compatibility with EtherCAT devices from different manufacturers. This ensures smooth integration when deploying these devices into an existing topology.

Engineered for Reliability

Implementing a robust and flexible topology requires hardware specifically designed for the industrial edge. Moxa’s EJS Series industrial EtherCAT junctions are engineered to be at the center of your high-performance network. The rugged and compact EJS Series offers the flexibility necessary to build resilient and adaptable EtherCAT network architectures to meet modern automation demands with maximum uptime and operational resilience.

Ready to Strengthen Your EtherCAT Network?

If you are using EtherCAT daisy-chain topologies, understanding how to mitigate the inherent risks is your next critical step toward operational excellence. In our latest tech note, we explore how to identify potential failure points and implement a more robust network architecture using EtherCAT junctions.

Download the tech note here

Related Story

MOXA Next-Generation LAN Firewalls: Enhancing Industrial Security and Reliabilit

Cyberattacks on critical infrastructure have become an all-too-familiar reality. While no longer shocking headline news, their effects are far-reaching, disrupting essential services that people and organizations rely on daily. From power grids to transportation systems and water treatment facilities, these infrastructures are at the heart of modern life and are highly vulnerable to cyber threats.