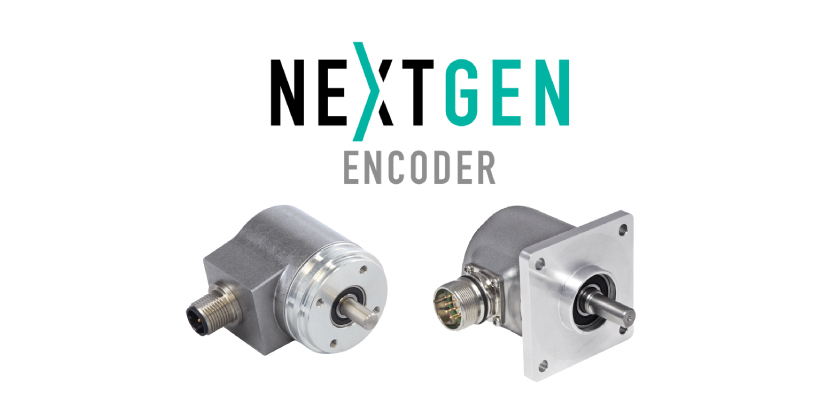

POSITAL Launches a New Generation of Incremental Encoders

February 28, 2023

POSITAL has launched a major upgrade to its IXARC family of incremental rotary encoders. These encoders feature new magnetic sensor technology and more energy-efficient embedded microcontrollers. While remaining mechanically and electrically compatible with earlier models, the new encoders will benefit customers by reducing power consumption – an important consideration in complex applications where multiple devices are connected to the control system.

These updated encoders are just the first of a series of products that POSITAL will be rolling-out over the next year. “Our aim here is to improve the performance, ease-of-use, and availability of our encoders and inclinometers,” says Christian Fell, head of POSITAL’s American operations. “This program, labeled NeXtGen, will update the core technologies used in our products, both to improve performance and to strengthen our supply chains.”

Christian Fell, Head of POSITAL’s American Operations

The new IXARC incremental encoders make use of a TMR (tunnel magneto-resistance) sensing technology in place of the Hall-effect sensors used on previous models. TMR sensors offer higher magnetic sensitivity, creating possibilities for improved resolution. TMR sensor are also less temperature sensitive and more energy-efficient than their predecessors. POSITAL will introduce TMR technology across its full range of rotary encoders, including absolute industrial encoders and its extensive line of kit encoders. The TMR sensors will be connected to a new generation of microcontrollers that offer a 60% energy consumption improvement over older components and can support new signal processing algorithms.

Another goal of NeXtGen is the simplification and rationalization of the company’s supply chain. Fell continues: “The past few years have brought home the importance of robust supply chains. POSITAL’s NeXtGen products have been designed to reduce dependencies on single-source suppliers and to streamline production.”

The NeXtGen initiative is another step in POSITAL’S ongoing efforts to provide state-of-the-art products that meet customers’ most demanding requirements. Key milestones in this journey have included absolute optical encoders (1973), the introduction of magnetic encoders with a revolutionary Wiegand-powered rotation counter (2005), upgraded magnetic encoders with higher resolution and improved dynamic response (2013) programmable encoders (2014) and compact, cost-efficient kit encoders for electrical motors and drives (2017).

Fell concludes: “This is just the first of many exciting developments from POSITAL … stay tuned!”

Christian Fell, Head of American Operations

More Information

POSITAL Launches a New Generation of Incremental Encoders

Related Story

POSITAL Extends Product Finder Portal to Include Kit Encoders

The company has updated its online Product Finder tool to include the company’s extensive line of kit encoders.