ABB Collaborates with Lhyfe and Skyborn on One of Europe’s Largest Renewable Hydrogen Projects

May 11, 2023

- Together with Lhyfe and Skyborn, ABB will drive large-scale integration of production of offshore wind renewable hydrogen into the energy system in the SoutH2Port project

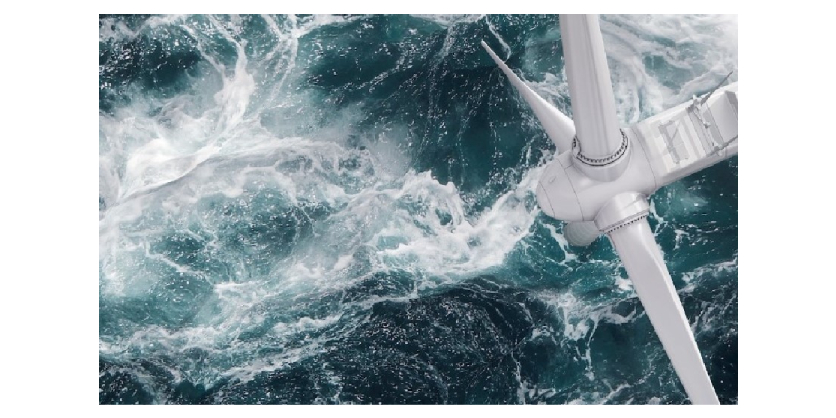

- Powered by Skyborn’s planned offshore wind farm, the plant in Söderhamn, Sweden, will produce around 240 tons of hydrogen per day, equivalent of around 1.8 million barrels of oil per annum

- ABB will apply critical expertise to optimize the integration of the hydrogen and electricity production across entire ecosystem including automation, electrical and digital technologies

ABB is collaborating with Lhyfe, a world pioneer in the production of renewable hydrogen, and Skyborn, a global leader in renewable energy, to jointly realize and optimize one of Europe’s most ambitious renewable hydrogen projects ever, SoutH2Port.

The new hydrogen production plant, operated by Lhyfe and Skyborn, will be located in the municipality of Söderhamn, Sweden, and connected to Skyborn’s 1 GW offshore wind farm in nearby Storgrundet. When fully operational, it is expected to produce about 240 tons of hydrogen per day, with an installed capacity of 600 MW, making it one of the largest suppliers of renewable hydrogen in Europe.

“This collaboration is a key part of our strategy in both the hydrogen and offshore wind markets,” said Brandon Spencer, President of ABB Energy Industries. “Creating a seamless supply chain, through partnerships such as these, is essential to accelerate the energy transition. Hydrogen plays a crucial role in helping achieve the world’s climate goals when it comes to decarbonizing the industrial and transportation sectors.”

Brandon Spencer, President of ABB Energy Industries

As part of the Memorandum of Understanding signed between the companies, ABB will apply critical expertise to optimize the integration of the hydrogen and electricity production across the entire ecosystem including automation, electrical and digital technologies and drive the development of scalable, commercial energy transition projects in and around the region. The aim is to explore opportunities to tie-in Power-to-X conversion technologies turning renewably sourced electricity into carbon-neutral energy carriers, such as hydrogen, and storing the energy for later use.

“We are delighted to have such a global technology leader as ABB, who shares our conviction in the Power-to-X potential of the SoutH2Port project, join our collaboration with Lhyfe. I look forward to taking this project to the next level with the help of ABB and their unrivalled expertise within this field,” said Achim Berge Olsen, Chairman of Skyborn Renewables Sweden.

Achim Berge Olsen, Chairman of Skyborn Renewables Sweden

“By combining our expertise and solutions, we can cost-effectively and safely expand the value creation attached to the scale up of renewable hydrogen production,” said Taia Kronborg, co-founder and Chief Business Officer at Lhyfe. “Skyborn’s track record in offshore wind power, Lhyfe’s expertise in renewable hydrogen production coupled with ABB’s technological expertise creates new opportunities for enabling Power-to-X solutions linked with renewable hydrogen production at scale.”

aia Kronborg, co-founder and Chief Business Officer at Lhyfe

The new plant will support the decarbonization of the Swedish energy system, either directly with hydrogen supply or by further downstream production of refined fuels such as methanol, sustainable aviation fuel or ammonia – contributing to the government’s plans to become the world’s first fossil-free welfare country by 2045. SoutH2port will also further contribute to boosting the attractiveness and competitiveness of the region and local society through the creation of new jobs and business opportunities.

More Information

Related Story

Research Reveals Energy Concerns Impacting Business Competitiveness, The Workforce and Decarbonization

Research shows that businesses around the world remain concerned about the impacts of energy security and prices, which could be a catalyst for a range of environmental, social and economic ripple effects. According to ABB Electrification’s Energy Insights survey1 of 2,300 leaders from small and large businesses across a range of sectors, 92 percent of respondents feel that the continuing instability of energy is threatening their profitability and competitiveness. Energy costs and insecurity are having a significant impact on the workforce with decreased investment in employees. Business leaders are also concerned about potential impacts of meeting their sustainability targets.