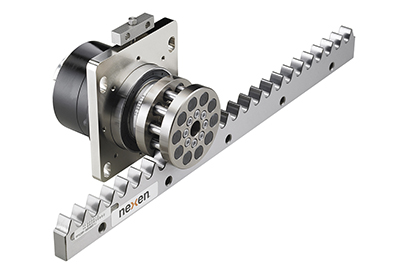

Nexen Introduces Alternative to Traditional Drive Systems: Roller Pinion System in Corrosion Resistant Stainless Steel

May 30, 2019

Nexen Group, Inc. introduces a stainless steel version of its patented precision roller pinion system (RPS). The Nexen RPS engages two teeth simultaneously to achieve superior accuracy with zero backlash at any length. The system is also extremely quiet, and 99% efficient. Stainless steel makes the system extremely corrosion resistant, with a long life of up to 36 million meters. Nexen’s RPS provides a low maintenance, durable alternative to rack and pinion, ball screw and belt drive technology. The RPS is used for a wide range of applications including laser cutting, plasma cutting and gantry applications.

Highlights include:

- High speeds: 11 m/s (36 ft/sec)

- Superior accuracy: +- 50 um

- Zero backlash

- Unlimited length (custom lengths and modular components available)

- Long life: up to 36 million meters