How to Achieve Next-Level Clarity for Complex GenAI Server Boards

December15, 2025

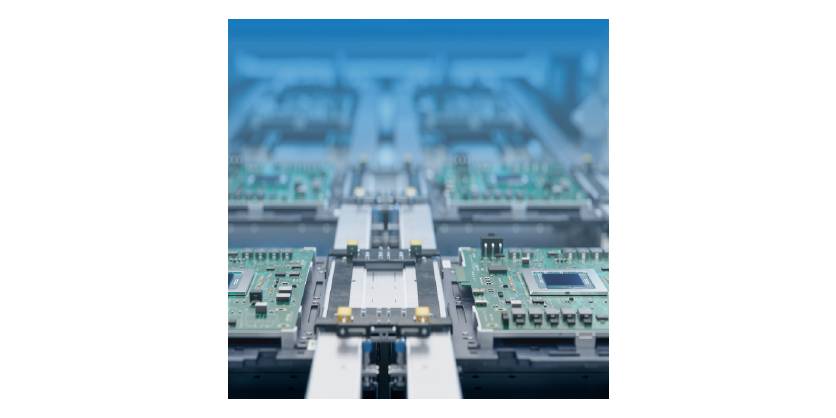

Discover why 3D CT X-Ray is a game-changer for AI hardware quality inspection of server boards

Welcome to the Age of Invisible Defects

Generative AI is everywhere, from writing your emails to generating art and code. But the real magic happens on server boards so densely packed, even the best engineers can’t see all the connections. As these boards get more complex, traditional inspection methods just can’t keep up.

Why GenAI Boards Are a Quality Nightmare

- Densely packed components: Think skyscrapers on a postage stamp.

- Hidden connections: Press-fit pins, through-hole leads, and fine-pitch BGAs are buried under heatsinks and shields.

- Zero room for error: One escape can cost an assembly line millions.

Forget 2D X-Ray systems, today’s GenAI boards need full 3D CT results, like those from OMRON’s VT-X750, to catch what the naked eye (and other X-Ray technologies) miss.

What makes 3D CT X-Ray a game changer?

- See every layer: Volumetric scans reveal hidden joints and solder connections.

- Automated, repeatable results: Advanced algorithms spot defects and measure quality, with no guesswork.

- Custom recipes: Tweak settings for each component, from massive BGAs to delicate chiplets.

Real-World Challenges, Real-World Solutions

- Press-Fit Connectors: 3D CT finds misaligned or damaged pins that 2D scans miss.

- Through-Hole Components: Only a full-barrel scan ensures proper solder fill and lead insertion.

- Fine-Pitch BGAs & Chiplets: High-res slices and smart software catch defects, even under thick metal shields.

- Stacked Packages: Adjustable focus and multiple angles guarantee every solder joint is checked.

Pro Tips for Flawless Inspection

- Use high-voltage X-Ray and multiple angles for tough spots.

- Let automation do the heavy lifting for speed and accuracy.

- Leverage different imaging parameters to further optimize results

- Rely on high-quality results and sophisticated algorithms

The Bottom Line: Don’t Let Defects Hide

As GenAI hardware gets more advanced, only 3D CT X-Ray inspection can keep up with the pace and complexity. OMRON’s VT-X750 is built for this challenge, delivering fast, reliable, and crystal-clear results for the world’s most demanding AI hardware.

More Information

Explore Omron’s inspection solutions

Related Story

The Future of AI and Vision Technology in Inspection and Quality Control

The landscape of AI and vision technology in inspection and quality control is set to transform with the development of more generalized algorithms. These advanced systems will be capable of tackling a wide range of inspection challenges, moving away from the current trend of specialized algorithms designed for specific tasks. This evolution promises to enhance the versatility and efficiency of AI, making it a more powerful tool for industries that rely on precise and reliable inspection processes.