WAGO Expands 750 Series with New Functional Safety I/O Modules

September 12 2025

WAGO Expands 750 Series with New Functional Safety I/O Modules

WAGO is introducing three functional safety I/O modules to be used with WAGO’s PFC controllers. These new 750 Series modules have four safe inputs along with either two safe outputs at 10 A/24 VDC, or four safe outputs at 2 A/24 VDC each. The power outputs operate in both bipolar (high-side/low-side switching) and unipolar (common potential on one side of the load) modes. The module monitors short circuits, cross circuits, and 24 V power supply from separate sources.

The 750 Series modules contain internal logic that can be programmed with WAGO’s I/O-CHECK and Safety Editor software. Using these modules, safety-related applications up to SIL3/PLe can be implemented without the need for a safety PLC. These modules have been evaluated by UL in compliance with the UL/CSA 61010-1, UL/CSA 61010-2-201 and UL 121201, and CSA-C22.2 No. 213 standards.

This means customers can implement functions like E-Stop or light curtain response without investing in a full safety controller, reducing hardware costs and simplifying system architecture.

For small, decentralized applications, this is a game-changer. Customers no longer need to wire safety signals through a central controller or rely on complex fieldbus communication. Instead, they can build logic directly into the module – saving space, reducing wiring, and speeding up commissioning.

The 750 Series modules also support virtual inputs and outputs, allowing integration with higher-level control systems when needed, but keeping time-critical safety decisions local for faster response.

Now, with logic embedded in the module, and configuration handled through an intuitive software interface, WAGO empowers users to deploy safety functions more efficiently and affordably, especially in compact or standalone machine environments.

What are the benefits of WAGO Safety Logic Modules?

- Certified for SIL3 / PLe Functional Safety – They support safety functions up to SIL3 and PLe / Cat. 4, meeting international standards like IEC 62061 and ISO 13849-1, and IEC 61511 for high-risk industrial applications.

- Engineered for Modern Decentralized Safety Architectures – They can integrate directly into the WAGO I/O System 750 and 753, enabling distributed control without the need for a separate safety PLC. This simplifies wiring and supports scalable, modular designs.

- No Need for a Safety-Rated PLC – It provides safety functions such as Emergency Stop and Two-Hand Control that can be implemented using WAGO Basic Controller 100, PFC100, PFC200, and PFC300, eliminating the cost and complexity of a dedicated safety PLC.

- Flexible Configuration – These modules are available in multiple variations (e.g., 4FDI/4FDO, 4FDI/2FDO) with high-current outputs up to 10A, and configurable via the WAGO Safety Editor (SEDI) for both online and offline parameterization.

About WAGO:

Innovation is at the heart of everything they do at WAGO. From our pioneering CAGE Innovation is at the heart of everything they do at WAGO. From our pioneering CAGE CLAMP® spring pressure connection technology to our extensive range of Interconnect, Interface and Automation solutions, such as the fieldbus independent WAGO-I/O-SYSTEM, their customers count on the unconditional performance and reliability of their products to ensure the safe, efficient operation of their systems every time.

More Information

For more information about WAGO’s 750 Series modules, visit https://www.wago.com/ca-en/safety-logic-modules

Related Product

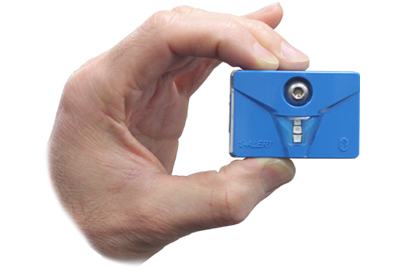

Introducing the New WAGO App: Your Jobsite Sidekick

Stay connected with WAGO wherever you go. Download the WAGO App to access product details, documentation, configuration tools, as well as local distributors — all from your mobile device. Scan the QR code to get started on the App Store or Google Play.