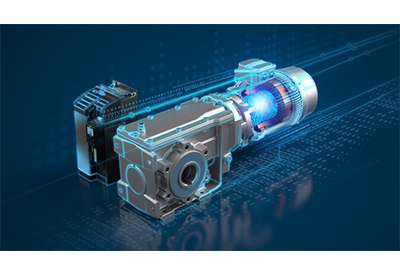

Siemens: SIMOGEAR Reluctance Geared Motor

May 27, 2019

The new SIMOGEAR synchronous-reluctance drive system consists of SIMOGEAR standard gear units, SIMOTICS synchronous-reluctance motors and SINAMICS frequency converters. With this solution, Siemens is widening the SIMOGEAR geared motors portfolio by newly combining the gearbox with the reluctance motor from SIMOTICS as a completely new offering for the customer.

By combining the aforementioned products the customer benefits especially from the efficiency class compared to IE4, which scores with higher efficiency and lower losses, especially in a partial load than to comparable asynchronous motors. Highly energy efficient, the motor heats up less and provides a high operation reability due to its excellent thermal behavior. Because of that high service factors are achieved.

This solution also boasts with high dynamics thanks to the motor’s lower moment of inertia and optimized control. Commissioning is established quickly and easily by entering the motor code into the converter. The constant torque-speed characteristics up to the rated speed make an external fan redundant. In the drive system, all components are perfectly coordinated together.