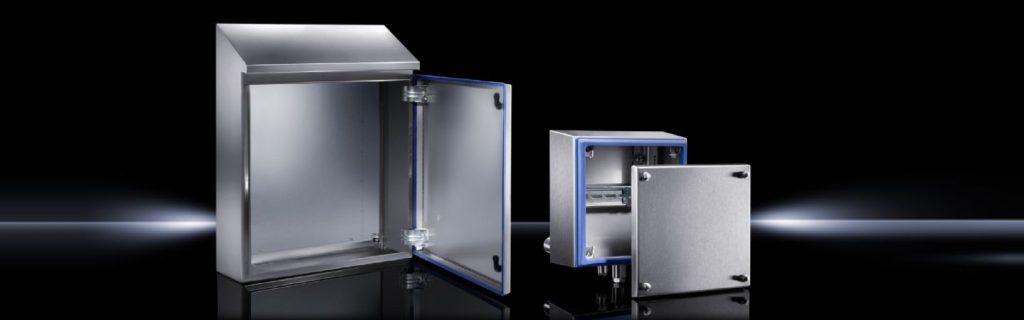

Complete Solutions for Hygienic Manufacturing Processes

January 17, 2023

Complete Solutions for Hygienic Manufacturing Processes from Rittal. Tough production conditions, digitalization and the growing importance of food safety pose great challenges for the food industry. Looking beyond hygiene and process reliability, resource consumption and sustainability are also key drivers in this sector.

Food Safety – Hygiene – Digitalization – Efficiency

To remain competitive, today’s food industry must meet even higher standards in terms of hygiene, efficiency and digitalization. The challenge for industry professionals is to find answers to a number of questions:

- What type of control cabinet can I install in the individual hygiene areas?

- How can I reduce the CO2 emissions of my production?

- How can I ensure reliable and continuous traceability of the data?

- How do I massively reduce my energy costs?

Rittal solutions for this industry provide the ideal basis for this. Further information