Yaskawa America, Inc. Introduces Yaskawa Compass Software

July 2, 2020

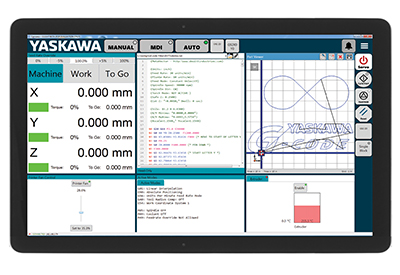

The Drives & Motion division of Yaskawa America, Inc. is proud to release Yaskawa Compass, a new software user interface tool for advanced manufacturing.

Yaskawa Compass is your CNC navigator, a graphical user software package applicable to multiple applications in 3D printing, shape cutting, machine tool and robotics.

“Compass is designed with creativity in mind allowing machine manufactures to brand and easily customize screens to include core machine attributes and customer needs with little programming requirements” stated Rosemary Burns, Yaskawa’s Advanced Manufacturing Segment Manager.

Coupled with the MP3300iec motion controller, Compass provides advanced plug-in solutions that you simply drop onto your screen. Prebuilt plug-ins include extruder, spindle, temperature control, stepper control, linear and rotary tool changer, 2D path planning and more. All plug-ins are developed in C#, so machine builders can also easily create and import their own machine plug-ins.

Key features of Yaskawa Compass include:

- – Landscape or portrait mode

- – Machine configurator

- – Screen configurator

- – Prebuilt Plugins

- – OEMs branding with company colors and graphics

- – Axis configurator

- – Auto, MDI and manual mode

- – Pop-up NC editor and messaging

- – Alarm history

- – Tool manager

- – Part cycle time measurement tools

- – 2D viewer with live TCP updates

To supplement the use of Compass with MPiec controllers, Yaskawa has added advanced motion control features to its MotionWorks IEC library. Some of these include bed leveling compensation, extruder pressure advance control, tangential control and ability to create custom G-codes and kinematics.

Burns added, “Consider hybrid machinery, Yaskawa Compass empowers machine manufacturers with versatility for both additive and subtractive applications to easily implement and customize features while streamlining their development cycle”

For more information, visit www.yaskawa.com.