Sweetch Energy and Rockwell Automation Optimize Unique Zero-Carbon Electricity Generation Technology

July 8, 2024

French renewables startup Sweetch Energy will rely on extensive domain expertise and global presence from Rockwell Automation help scale its osmotic power generation technology.

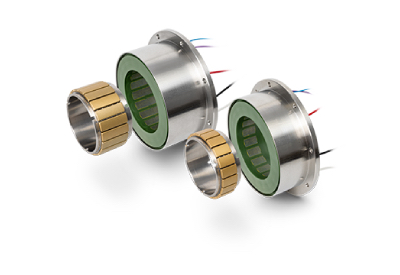

Osmotic energy is naturally generated by the difference in salinity between freshwater and seawater. The INOD® (Ionic Nano Osmotic Diffusion) technology developed by Sweetch Energy is the first technology of its kind to be marketed on an industrial scale.

Using Rockwell’s turnkey process control platform and visualization technology, Sweetch Energy will optimize its unique zero-carbon electricity generation technology in its first osmotic demonstrator plant at the Barcarin lock in Port-Saint-Louis-du-Rhône, France. The company plans to deploy several osmotic stations at the mouth of the Rhône to harness natural osmotic energy. These stations will represent up to 500 MW of carbon-free electricity production capacity, capable of supplying more than 1.5 million people – the equivalent to the population of cities such as Marseille and its surrounding areas, Barcelona, Amsterdam, or Montreal.

Manufactured using environmentally friendly bio-sourced materials, the osmotic generators can be located at any estuary or delta. Water is the only input in the process and is fully returned to the river mouth, with no chemical waste or pollutants created. And, unlike other renewables, it is not dependent on weather conditions and can produce clean electricity continuously.

Rockwell technologies will be used to automate, control, and monitor the system as well as optimize the process and power-generation efficiency. The technology to be deployed at the pilot plant is also highly scalable, allowing Sweetch Energy to create standardized, modular, with worldwide support for installations of any size, anywhere.

More Information

Learn more about Rockwell’s sustainably advantaged solutions

Related Story

Rockwell Automation to Increase Scale and Scope of AI in Manufacturing with NVIDIA

Rockwell Automation. one of the world’s largest companies dedicated to industrial automation and digital transformation, has announced it is collaborating with NVIDIA to accelerate a next-generation industrial architecture.