SEW-EURODRIVE: ATO5 – Industrial Gear Units to Go

January 19, 2021

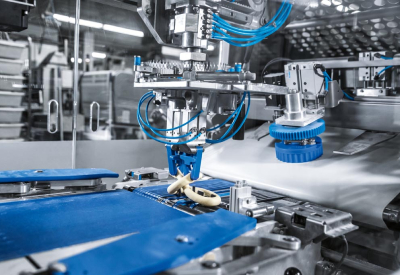

Powerful and robust industrial gear units are often associated with customized solutions and – for technical reasons – rather long delivery times. SEW-EURODRIVE is putting an end to this with the ATO5 range: The industrial gear units without design modifications – i.e. “Assemble-To-Order” – leave the factory just 5 working days after being ordered and and make their way to the place of use.

X.e and P gear units ready to deliver in five days

Excellent news if you’re in a hurry – whether you work in design, procurement or maintenance. Industrial gear units from SEW‑EURODRIVE are now with you even faster and ensure your application is up and running within a short space of time.

SEW-EURODRIVE’s ATO5 to go range (ATO = Assemble To Order) for shorter delivery times makes this possible. All ATO5 industrial gear units from the tried-and-tested SEW‑EURODRIVE modular system leave our plant just five working days after your order.

Standard Generation X.e helical and bevel-helical gear units in sizes up to 45 kNm and standard P series planetary gear units up to 360 kNm are available as ATO5 products – including almost all options. From March 2021, you can order Generation X.e gear units up to 175 kNm with reduced delivery time.

It doesn’t get faster than that. Unless you’re dealing with an emergency. If your machine is at a standstill, SEW-EURODRIVE can send you the replacement gear unit after just one working day. That’s the ultimate in flexibility and operational reliability for anyone in a hurry.