Regal Introduces Expanded Industrial Powertrain Capabilities

July 6, 2021

Regal Beloit Corporation, a global provider in the engineering and manufacturing of high-efficiency electric motors and power transmission products, is continuing to enhance its industrial powertrain capabilities. Regal, with its power transmission and motors offering, and deep domain expertise in a range of industrial end markets, combined with enhanced component integration and optimization capabilities, is now even better positioned to maximize uptime and reduce energy consumption in customers’ powertrain applications, whether for new builds or existing installations.

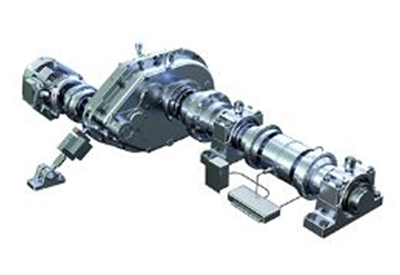

The Regal electromechanical powertrain offering encompasses a broad range of Regal-produced components (e.g., motors, speed reducers, gearing, couplings, bearings, belt drives and more) that can be integrated to create complete end-to-end solutions, customized to meet specific application requirements, and optimized to maximize energy efficiency and productivity. In addition to helping customers design, assemble and commission their powertrains, Regal can monitor a solution’s ongoing performance through its cloud-based Perceptiv™ internet of things (IoT) platform. Data collected and analyzed via Perceptiv can support a wide range of diagnostic and prognostic activities, enabling customers to sustain high performance from their assets.

“At Regal, we create a better tomorrow and endless potential for our customers by energy-efficiently converting power into motion,” said Louis Pinkham, Regal’s Chief Executive Officer. “We optimize our engineered mechanical power transmission components and motors to work better together, more efficiently and effectively. The ongoing asset monitoring we offer across the powertrain with Perceptiv intelligence helps to maximize uptime and prevent costly outages, while simplifying the maintenance, repair and operations experience for our customers.”

Pinkham continued, “Earlier this year, Regal announced a transformational merger with Rexnord’s Process & Motion Control business, which is on track to close in the fourth quarter. The merger is expected to further enhance our capabilities across the industrial powertrain, especially in higher-torque applications, where Rexnord is strong, while deepening our presence in attractive high-growth end markets such as renewable energy, aerospace and e-commerce, and in a broader set of geographies.”

Currently, Regal’s electromechanical powertrains are used within industries such as bulk and unit material handling, metals, pulp and paper, mining, and other critical industrial applications.