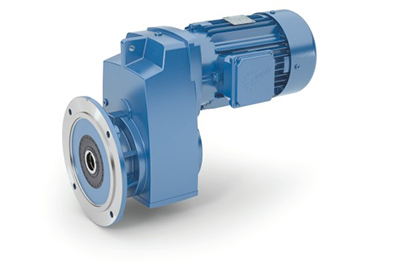

NORD: Powerful Agitation Gear Unit – Drive solutions from NORD with reinforced bearings

July 11, 2019

NORD DRIVESYSTEMS supplies reliable drive technology with reinforced bearings and increased bearing spacing for the processing industry. This ensures maximum radial and axial load capacities and longer service life of the gear units.

By their nature, agitator applications result in higher radial and axial loads on the gear unit. NORD DRIVESYSTEMS supplies application-specific options which feature high powers and efficiency. These include an agitator version (VL2 bearing) with increased bearing spacing and reinforced bearings as well as a Drywell version (VL3 bearing) with additional oil drip plate and leakage or oil sensor. The bearing spacing of the VL2 and VL3 versions is increased by attachments. The changeover to a larger gear unit and the associated costs are eliminated. In addition, NORD offers deliberately oversized bearings for use in agitators.

Find out more HERE.