New: PSNErope Mini – The Cost-Effective Solution for Safeguarding Conveyors from PILZ

July 6, 2022

Non-stop safety

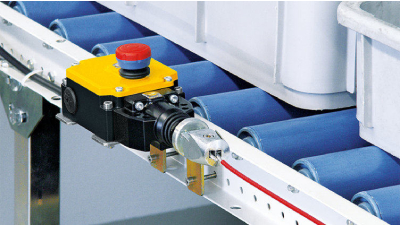

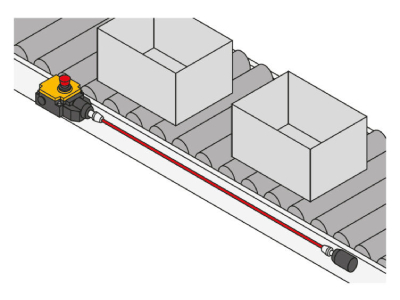

Whether on the assembly line or machine: where safety in the production area is concerned, the safe rope pull switches PSENrope are a proven, reliable solution. PSENrope switch off functional processes by manual operation. PSENrope provide maximum safety when it matters: the emergency stop function can be triggered at any point along the rope. With a rope length of up to 75 meters, they are suitable for safeguarding large plants.

With PSENrope mini you have a particularly compact, cost-efficient rope pull switch with a rope length of up to 30 meters, for reliable protection on conveyors or machines. The sturdy metal or plastic housing ensures that it is highly robust.

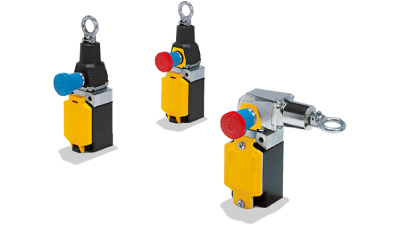

Thanks to versions with straight and angled head, PSENrope mini are flexible and simple to install in various assembly situations. In addition to the versions with E-STOP function there are also versions with integrated reset button, which are suitable for concealed installation within the application.

Simple, convenient safety solution

- •Simple installation and convenient management

- •Flexible to use even when protecting large systems

- •Extremely rugged thanks to robust finish and strong metal or plastic housing

- •Highly robust thanks to sturdy metal or plastic housing

- •Suitable for both indoor and outdoor use

- •High level of safety as wiring space is physically separate from mechanics

- •Cost-effective thanks to the combination of emergency stop and pull-to-release

Features of the rope pull switch

- •Designed for applications up to: PL e of EN ISO 13849-1, SIL CL 3 of EN/IEC 62061

- •Integrated E-STOP pushbutton

- •Contacts: 2NC, 2 NO

- •Versions with reset function (PSENrope mini)

- •Protection type: IP67

Durable – even under extreme conditions

The safe rope pull switches PSENrope are robust and flexible, making them a proven, reliable solution where safety in the production area is concerned. As the operating range of rope pull switches is limited only by the length of the rope, even large plants can be safeguarded using PSENrope.

Industry uses of the rope pull switch

- •Packaging industry

- •Pulp and paper industry

- •Airports

- •Automotive Industry

PILZ’s product range: Safe rope pull switches PSENrope

Safe rope pull switches PSENrope: Safe rope pull switches PSENrope are flexible to use, easy to install and simple to operate. Whether it’s a first-time installation or upgrade: the rope pull switches simplify installation with their sophisticated details.

Accessories for safe rope pull switches: Perfectly compatible with PSENrope: Block rope pulleys, ropes, guide rollers, tension springs, multiple interfaces PDP67 etc.

Safe rope pull switch PSENrope mini: With PSENrope mini you have a particularly compact, cost-efficient rope pull switch with a rope length of up to 30 meters, for reliable protection on conveyors or machines.

Connection technology: Many compatible cables enable many advanced functionalities. Here you can select the solutions that’s right for you.

To learn more about the New PSNErope Mini from PILZ, click here