New FHA Integrated Drive from Harmonic Drive

November 12, 2021

The FHA-C mini Series is a family of extremely compact actuators that deliver high torque with exceptional accuracy and repeatability. As part of the FHA-C mini family, an integrated servo drive version utilizing CANopen® communication is now available. This evolutionary product eliminates the need for an external drive and greatly improves writing while retaining high-positional accuracy and torsional stiffness in a compact housing. This new mini actuator product is ideal for use in robotics.

Since it communicates via CANopen, only 4 conductors are needed: CANH, CANL, +24VDC, 0VDC. A single-turn 14bit (16384 cpr) gear output sensing encoder has been integrated along with a single-turn 15bit (32768 cpr) motor input sensing encoder providing a true absolute encoder that does not require a battery within 360° of rotation of the output. Typical multi-turn encoders monitoring the motor input shaft require a battery to store the current position when power is lost to the system; however, the dual absolute encoders overcome this need. In other words, No Battery Required. When power is restored, the actuator knows its position.

Key Features:

- Actuator + Integrated Servo Drive utilizing CANopen communication

- 24VDC Nominal +7 to 28VDC Supply Voltage Range

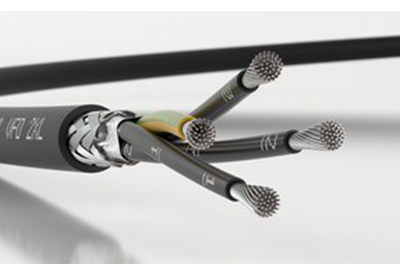

- Single Cable with only 4 conductors needed: CANH, CANL, +24VDC, 0VDC

- Zero Backlash

- Dual Absolute Encoders

- Panel Mount Connectors with 4 exit options

- Output Sensing Encoder 14bit (16384 cpr) resolution

- Input Sensing Encoder 15bit (32768 cpr) resolution

- Control Modes Including Torque, Velocity, and Position Control, CSP, CSV, CST

- Harmonic Drive HDL Software for initial tuning, commissioning, and analysis

For more information on ordering, specifications, dimensions, etc. click here