NEW Compact Extra-Low Voltage Drives

January 10, 2022

The new compact extra-low voltage drives are absolutely at home in the materials handling technology used in warehousing systems. They offer your applications high running smoothness, overload capacity and flexibility. They have a diverse range of potential uses, and they fit like a glove into even small installation spaces.

Demands in consumer and industrial logistics are changing. Orders are having to be fulfilled ever faster and container sizes are getting smaller. At the same time, factory logistics, and therefore also warehouse technology, are becoming more flexible, while conveyor modules are getting smaller and materials handling technology is increasingly mobile. Shuttle vehicles are taking over from rigid systems in certain areas – logistics and warehouse technology are changing. These changes are increasing the level of automation and decreasing the installation space for gearmotors. How much drive technology weighs plays a vital role, particularly when it comes to mobile systems. The associated drive systems must therefore also become more decentralized, more compact, more lightweight and more networked in order to efficiently meet these requirements.

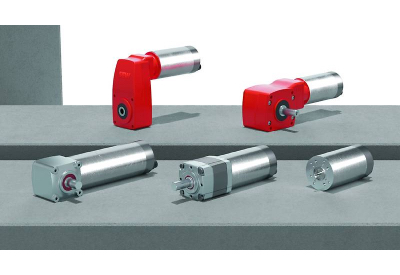

We offer decentralized compact extra-low voltage drives precisely in order to meet these needs. The gearmotors consist of a compact motor with a 48 V DC voltage supply. These are compatible with compact planetary, right-angle, and right-angle planetary gear units. Together, they make up a drive solution with a compact construction for decentralized systems.

The compact motors are electronically commutated internal rotor motors with a high power density and dynamics. The motors feature fully integrated control electronics with an analog and digital interface. The parameters of these interfaces can be configured via an RS485 engineering interface. This enables users to make flexible use of the motors and adapt them to suit a variety of applications.

Engineering software DCAShell (DE / EN): The engineering software DCAShell for compact extra-low voltage drives is necessary to set parameters and operating data and is also needed for the diagnosis of operating states.

To DCAShell

Drive benefits

-

Overload capacity

thanks to a gear unit selection for high peak loads

-

Running smoothness

thanks to optimized gear wheel geometry in a compact design

-

Customized

thanks to a large number of motor and gear unit combinations with a variety of reduction ratios in the first and second stage

-

Flexible

since the symmetrical mounting position and lack of offset enable a range of installation positions

Typical applications:

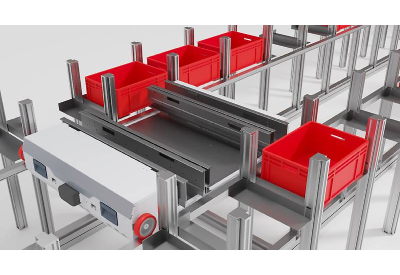

The new compact extra-low voltage drives are absolutely at home in warehouse technology and storage systems. Applications in stationary materials handling technology include roller and accumulating roller conveyors, belt and chain conveyors, lifting modules and corner transfer units, turning devices and rotary tables, trolleys, pallet transfer shuttles, vertical conveyors and hoists, stacking devices, container storage systems and sequencers, pushers, and additional stationary materials handling technology.

However, there are also applications for the new compact extra-low voltage drives in mobile materials handling technology , for example as simple shuttle travel drives and load handling devices, on operating devices (SRS, automatic small parts warehouse), in sorters with a belt or tray, pallet transfer shuttles or automated guided vehicle systems.

Stystem benefits

-

More compact vehicles

thanks to optimized and integrated drives

-

Greater flexibility

thanks to access to an end-to-end automation system

-

System safety

thanks to SEW‑EURODRIVE’s service availability

Areas of operartion

Lift modules and corner transfer units

Logistics implies more than conveying along straight routes or one level. That’s why our compact extra-low voltage drives are able to convey around corners or drive lift modules.

Belt and chain conveyors

Our compact extra-low voltage drives are also tailored to the demands of continuous duty. No matter if packaged goods or light bulk material – our drives transport anything up to 50 kg.

Rotary units and rotary tables

If your conveyor systems cross each other or if they need to feed goods in and out, our compact extra-low voltage drives also help you efficiently with turning devices.

Linear conveyors and accumulating roller conveyors

These are getting ever faster and lighter. Also, flexible, controlled stopping of the packaged goods must be ensured – an optimum environment for our new compact extra-low voltage drives.

Pushers and format adjustment

Diverse goods with different dimensions are transported on your belt? No problem! Our new compact extra-low voltage drives with high overload capacity also move pushers and format adjusters reliably.

Learn more about SEW-EURODRIVE’s compact, extra-low voltage drives by clicking here