High Availability Cloud Connectivity for Sensors: IO-Link Masters by Pepperl+Fuchs Are AWS Partner Qualified Devices

November 9, 2022

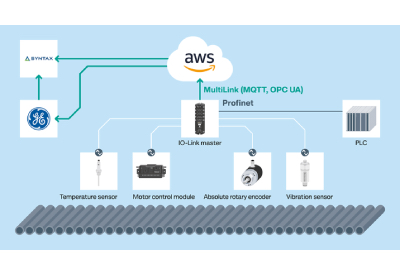

Publishing process and status data from sensors to cloud applications in manufacturing plants is one of the key requirements for the IIoT and Industry 4.0 principles. With the official qualification of the ICE2 and ICE3 IO-Link masters as “AWS Partner Devices”, Pepperl+Fuchs is consolidating its position as a leading provider of IIoT sensors and connectivity, offering users in the AWS ecosystem access to a broad portfolio of sensors for their predictive maintenance and condition monitoring applications. These sensors can be integrated easily to AWS-based applications via MQTT or OPC UA, enabling measurement and status data to be processed in a cloud-based data historian.

IO-Link Master as Central Component for Sensor Integration

The IO-Link masters of the Pepperl+Fuchs “Comtrol” brand are now listed in the AWS Partner Device Catalog and act as a central component for the connection to the AWS cloud environment: These fieldbus modules not only support real-time fieldbus protocols (Ethernet/IP or PROFINET) for the connection to deterministically operating industrial controllers, but also offer a completely web-based configuration concept and OPC UA, MQTT and REST API communication. This makes it possible for users without knowledge of fieldbus systems and PLC programming to implement stand-alone applications quickly and easily.

Thanks to the multilink technology, hybrid approaches can be implemented, in which the PLC runs time-critical processes and aggregated status data is transmitted in parallel via OPC UA or MQTT to AWS-hosted systems (e.g. by GE Digital or by Syntax).

Elegant Solution for Retrofits

If existing plants are to be retrofitted to future-proof IoT standards, the combination of AWS cloud technology and Pepperl+Fuchs sensor technology delivers untapped potential: On one hand, the entire Pepperl+Fuchs portfolio of IO-Link sensors and associated masters is available from a single source. On the other hand, existing standard sensors without IO-Link capability can be integrated into the overall architecture using IO-Link converter modules from Pepperl+Fuchs.

AWS and its partner network enable seamless IIoT solutions using interface components and sensors from Pepperl+Fuchs for simple integration to a variety of cloud-based applications.

Highlights

- •Multi-protocol IO-Link master for connection of IO-Link sensors to AWS cloud

- •Simple integration and commissioning thanks to web-based configuration

- •Different topologies can be implemented

- •Large portfolio of IoT sensors and interface components from a single source

- •Future-proof retrofit of existing systems

- •Converters for easy integration of digital and analog sensors without IO-Link interface

To learn more, click here