Flexible Connection Solutions for Printed Circuit Boards – HARTING with “All for PCB” Solutions for Superior Modularity, Flexibility and Speed

November 24, 2021

Modularity and flexibility are gaining increasingly higher significance in device development: Due to digitalisation and industrial transformation trends, development times for new devices are becoming increasingly shorter, while prototyping is playing an ever more vital important role. Moreover, the limited choice of available standard components often hampers device development. HARTING offers PCB connectors that meet the industry’s demands for modularity, flexibility and accelerated device development.

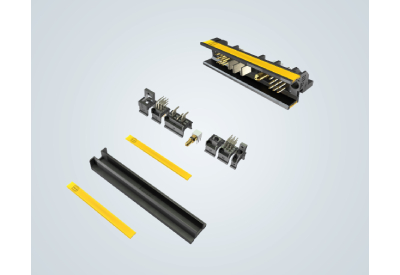

The expedient solution goes by the name of har-modular® – a modular PCB interface that can be individually configured online by any developer. This entails a tremendous reduction in the workload for device developers – regardless of whether it’s a matter of rapid prototyping, a small series or an entire product series. The modular construction kit with a billion possible combinations certainly leaves nothing to be desired. Customised solutions from batch size 1 save time, costs and nerves in development and facilitate the ever-shorter processes involved in turning out new industrial devices. Developers adapt the connector to their requirements and not the other way round. Har-modular® is a modular building block concept: the various different modules enable a billion possible combinations.

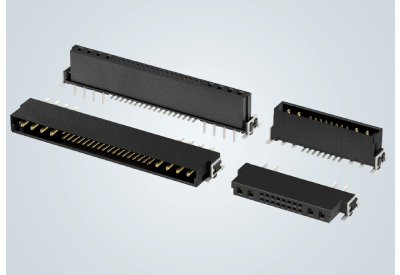

The har-flex® connectors with 6-100 contacts for signals, power or data follow a similar but markedly reduced approach with a pitch of 1.27mm. Different heights for mezzanine applications, the space-saving connection of ribbon cables and the high manufacturing quality for automated soldering processes are convincing factors in miniaturised PCB applications. Har-flex® is ideal for use in miniaturised PCB applications.

For more information, visit Harting here