Reliable Wireless Edge Computing with MOXA’s Quad-Core Arm-Based Computers

August 25, 2025

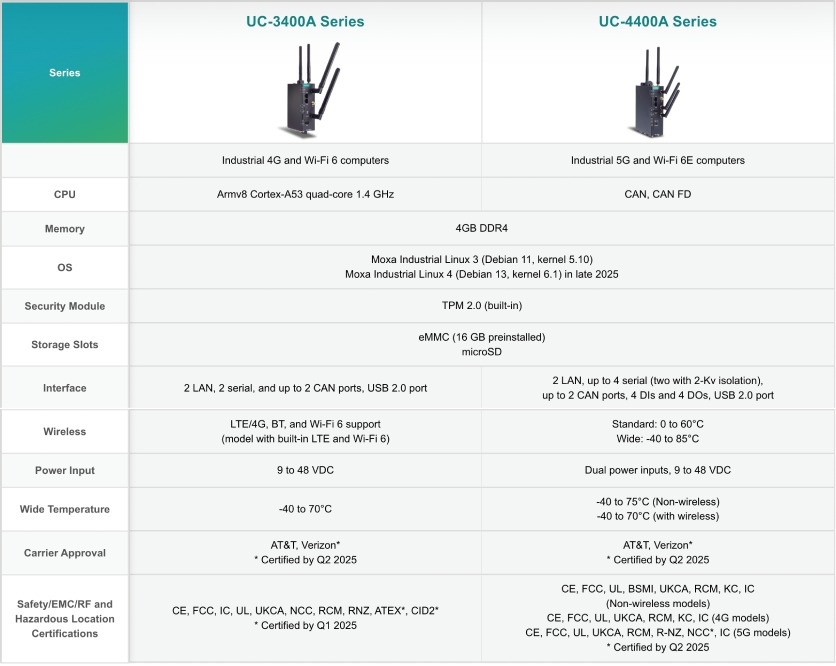

Industrial environments, such as those in renewable energy, heavy industries, and oil and gas, demand rugged computing solutions that offer uninterrupted wireless connectivity to collect and transmit critical edge data to the cloud. The Moxa UC-3400A andUC-4400A Series computers are designed to address these challenges, offering Wi-Fi, LTE, and 5G capabilities, a compact design suitable for space-constrained installations, and robust certifications for hazardous environments.

Expanding its Arm-based industrial computing portfolio, Moxa introduces the UC-3400A and UC-4400A Series, engineered for 64-bit quad-core performance and IEC 62443-4-2 SL2 security compliance. These advanced computing platforms provide enhanced wireless functionality, reducing maintenance efforts and simplifying system operations. With purpose-built software and flexible interfaces, these industrial computers facilitate seamless automation across a wide range of applications.

Key Advantages

Reliable Industrial Performance

- 5-year warranty for long-term reliability

- Moxa Industrial Linux with 10-year long-term support

- Certified for use in harsh conditions (CID2, ATEX, CE, FCC, UL)

- Certified for use in harsh conditions (CID2, ATEX, CE, FCC, UL)

- Redundant network and system design for increased uptime

Comprehensive Security Features

- Built to meet IEC 62443-4-2 SL2 security standards

- Chain-of-trust Secure Boot authentication for verified startup and updates

- Security Hardening Guide and built-in protection tools for enhanced security

Simplified Management & Deployment

- Moxa Swift for large-scale device provisioning and deployment

- Moxa Computer Interface Manager (MCIM) provides unified cross-device I/O management

- One-step backup and recovery for easy system restoration

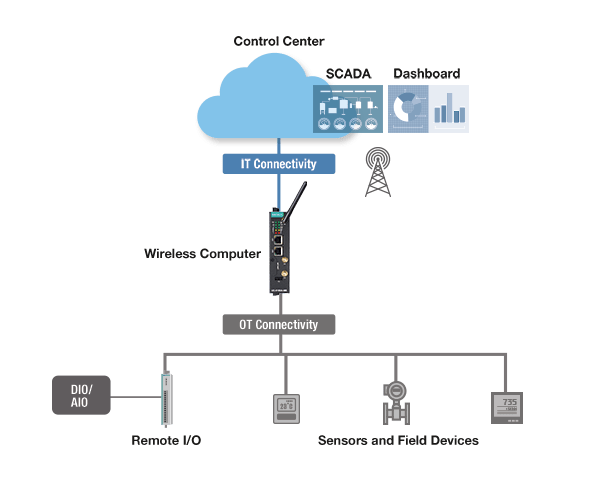

Leveraging Wireless Capabilities for Edge Computing

By eliminating the limitations of physical cabling, the UC-3400A and UC-4400A Series enable seamless wireless connectivity across remote sites. These solutions help organizations transition to modern OT infrastructure, reducing installation costs and enhancing automation efficiency through remote management capabilities.

Wireless Solutions for High-Performance Data Transmission

Optimize OT Infrastructure With Reliable and Secure Wireless Computers

Wireless Technologies Bring Efficiency to Data Transmission

Wireless Solutions Optimize Data Transmission in Challenging Environments. The UC-3400A and UC-4400A computers are equipped with dual wireless capabilities, supporting 4G/5G and Wi-Fi 6/6E for reliable operation in harsh conditions.

Automatic Network Failover Ensures Continuous Connectivity

Moxa Connection Manager (MCM) enables users to configure multiple network interface profiles. In the event of a connection failure, MCM automatically switches to the highest-priority backup connection.

Streamline Large-scale Deployment With Effortless Provisioning

Scalability With Streamlined Provisioning Moxa Swift offers an intuitive web-based interface to configure and provision multiple devices simultaneously, ensuring consistency and reducing deployment time.

Advanced 64-bit Arm-based Computing With 5G/LTE/Wi-Fi 6 Connectivity

Powerful 64-bit Arm-Based Computers With 5G, LTE, and Wi-Fi 6

Maximize Industrial Efficiency With Real-time Machine Health Monitoring

Durable, low-power industrial computers collect sensor data in harsh environments, transmitting it to the cloud for real-time monitoring and predictive maintenance.

Enhance Semiconductor Manufacturing With 5G-Enabled Computing

Integrated 5G and optional Wi-Fi connectivity eliminate the need for multiple devices, cutting costs and saving space in high-tech manufacturing environments.

Related Story

Future-Ready Industrial Wi-Fi with MOXA

As the Industrial Internet of Things (IIoT) expands, the need for robust wireless connectivity in industrial environments has skyrocketed. Industries such as factory automation, medical care, and mining increasingly rely on wireless networks to enhance operational efficiency. Moxa offers a comprehensive range of industrial wireless LAN products to meet these demands, featuring the latest Wi-Fi 6 technology for cutting-edge connectivity.