Eaton’s Battery Configuration Switch Provides EV Charging Flexibility

August 28, 2025

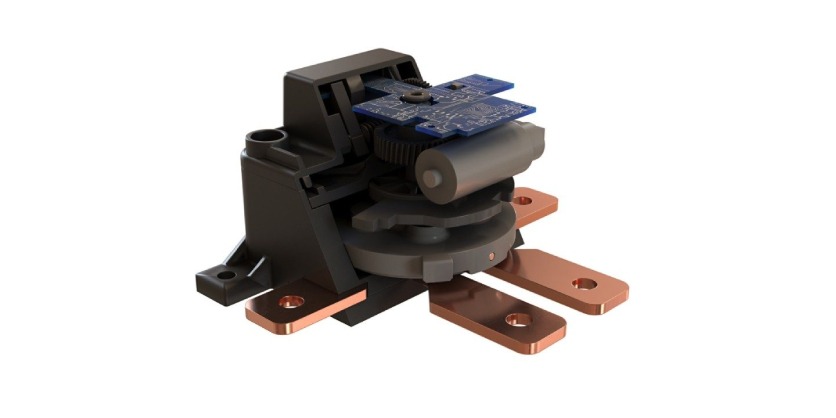

Intelligent power management company Eaton has announced it has partnered with Munich Electrification to develop and market its battery configuration switch (BCS), an advanced solution for 400-volt/800-volt dual string battery packs in electrified vehicles. This innovative, integrated, bi-stable device for parallel/series reconfiguration allows 800-volt vehicles to effectively charge via a 400-volt charger, while also offering numerous benefits compared to traditional solutions.

“At Eaton, we’re leveraging our extensive background in developing electrified mobility solutions to launch this promising new technology in partnership with Munich Electrification, which specializes in developing cutting-edge battery management systems. There are a lot of 800-volt vehicles in the market, but many charging stations can only supply 400-volt power. BCS provides charging flexibility to consumers who want access to an expanded network of DC chargers.”

Mark Schneider, President, Eaton’s eMobility

Designed for automotive, light commercial and UTV applications, Eaton’s BCS enables the reduction of up to 12 components in a battery disconnect unit, simplifying the system and streamlining packaging and assembly. Furthermore, the BCS minimizes contact resistance, enhancing overall system efficiency and performance by reducing the number of contact points required by conventional contactors.

Ensuring higher EV safety standards, the BCS has a mechanical interlock that prevents pack short circuits due to crashes, software bugs, or contactor malfunctions. The BCS can also maintain stable conditions when the electronic control unit loses power. Its bi-stable nature enhances efficiency during normal operations by eliminating the hold current of a traditional contactor, and also provides resilience against low voltage faults by maintaining a safe condition for a wide range of potential failure modes.

“We are thrilled to collaborate with Eaton in launching this groundbreaking new technology developed by our outstanding R&D team. Munich Electrification’s legacy of innovation in the EV battery industry combined with Eaton’s expertise in electrical switching and automotive manufacturing is helping us to solve our customers’ biggest challenges together. ”

Uwe Wiedeman, Managing Director, Munich Electrification

Eaton is an intelligent power management company dedicated to protecting the environment and improving the quality of life for people everywhere. We make products for the data center, utility, industrial, commercial, machine building, residential, aerospace, and mobility markets. We are guided by our commitment to do business right, to operate sustainably, and to help our customers manage power ─ today and well into the future. By capitalizing on the global growth trends of electrification and digitalization, we’re accelerating the planet’s transition to renewable energy sources, helping to solve the world’s most urgent power management challenges, and building a more sustainable society for people today and generations to come.

Eaton was founded in 1911 and has been listed on the New York Stock Exchange for more than a century. We reported revenues of $23.2 billion in 2023 and serve customers in more than 160 countries. For more information, visit www.eaton.com. Follow us on LinkedIn.

More Information

Learn about Eaton’s BCS technology and other vehicle electrification solutions.

Related Story

Eaton Canada Investing $15 Million to Power Canada’s Electrified Future

Eaton is investing CA$15 million to expand manufacturing capacity in Canada to meet growing demand as a result of the electrification of the country’s economy.

These investments will expand Eaton’s low-voltage manufacturing footprint by 20%, increasing its ability to produce the switchboards, switchgear and panelboards needed to support Canada’s electrified future. With a particular focus on the electrification of the country’s transport infrastructure, building systems and industrial processes, Eaton aims to complete the first phase of the project by Q3 2025, creating new manufacturing and engineering jobs in Ontario.