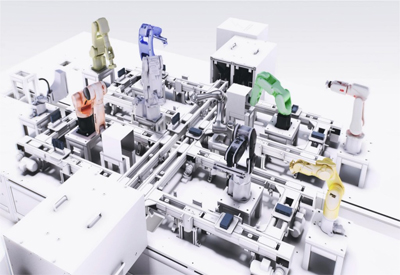

Cooperation for the Multi-vendor Integration of Industrial Robots into the TIA Portal

November 20, 2020

- Simatic Robot Integrator with Simatic Robot Library makes engineering easy for robots in the TIA Portal

- Universal interface supports integration by all robot manufacturers

- Re-usable program codes thanks to standard programming language

- Time savings of up to 30 percent for engineering

Siemens presents the Simatic Robot Library for the Simatic Robot Integrator – a new universal robot library for the TIA (Totally Integrated Automation) Portal, which replaces the previous manufacturer-specific libraries. The specification has been developed in close cooperation with robot manufacturers ABB Robotics, Comau, Epson, FANUC, Kawasaki Robotics, KUKA, Panasonic Industry, STÄUBLI, Techman Robot, Yamaha, and YASKAWA. In future, users will be able to program most of the robots available on the market in the TIA Portal using the Simatic Robot Library, and make use of standard operating concepts based on the Simatic Robot Integrator and Simatic HMI.

This means that created program codes and program packages will be re-usable, saving both time and money on a change of robot manufacturer. Integration into the TIA Portal also offers the option of easily combining robots with other technologies such as Simatic technology, cloud services, Edge data analyses or AI-based automation. Thanks to the standard environment in the TIA Portal, users achieve time savings of up to 30 percent when engineering new complete systems. The improved handling also increases efficiency, while identical faceplates for different manufacturers simplify operation. With the Simatic Robot Library, users do not require specific programming knowledge for a robot type; they only need to have knowledge of the TIA Portal. Simatic Robot Integrator is a ready-to-use application, which is directly integrated into a TIA Portal machine project. Combined with the new Simatic Robot Library, it enables users to download programming examples for operation and to control robots immediately after configuration. Simatic HMI offers popular online programming functions – regardless of the robot manufacturer – for inching, teach-in or path creation.