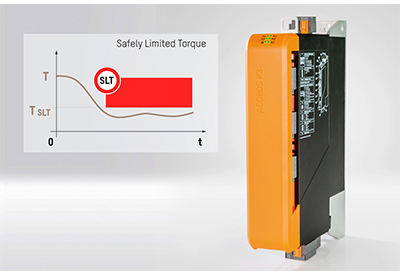

B&R Automation: Torque safely under control

June 20, 2019

B&R offers servo drives with safety function Safely Limited Torque

The B&R ACOPOS P3 servo drive is now also available with safety function Safely Limited Torque (SLT). This makes B&R one of the first manufacturers to offer this certified safety function. Safely Limited Torque safely monitors torque up to SIL 2 / PL d.

The torque is limited to the configured maximum value with the aid of current measurement integrated directly in the drive system. Since the safety function runs decentrally in the drive, an extremely short maximum fault detection time of 8 ms is guaranteed. Particularly when combined with other safety functions such as Safely Limited Speed or Safe Direction, the SLT function facilitates safe collaboration between human operators and their machines. The risk of operators being injured via pinching or crushing while working on a machine is minimized.

Safe prevention of mechanical overload

SLT can also be used to safely limit the load on mechanical systems. In this way, the safety function acts like a torque wrench that prevents over-tightening of screws. SLT can therefore be used as a protective measure against overloading drive axes and brakes. As a result, it is possible to use less expensive mechanical components since there is no need to account for torque spikes.

For more information, visit HERE.