Handling Nuclear Waste Safely with Pilz

August 20, 2025

No interruption due to Safety and Security

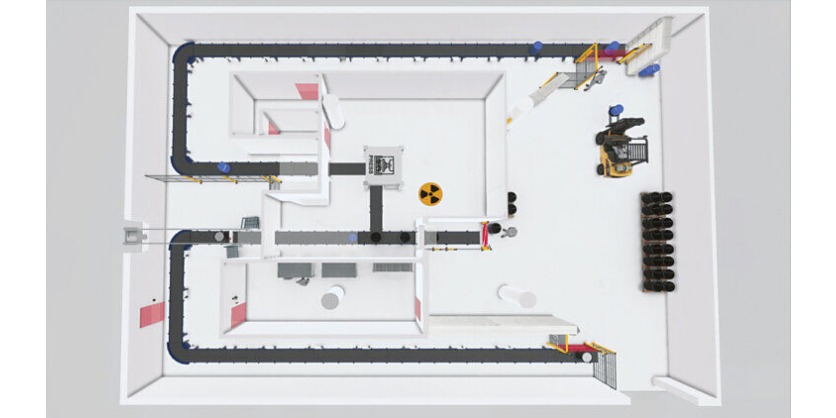

When handling radioactive waste, safety is COVRA’s top priority. That’s why the Dutch processing company planned a safety upgrade for its highly automated pressing and transportation system. Cylindrical drums containing radioactive waste are transported through the plant on conveyors and are compressed into flat blocks within a closed cell. Stacked in 200-litre drums, the blocks are then encased in concrete for storage. Should the plant come to a standstill, the data connection for registering the blocks must not be interrupted.

For this reason, the Pilz safety solution was integrated into the existing system of office automation and overall control for the roller conveyors. Comprehensive Identification and Access Management (I.A.M.) now ensures added Safety and Security.

I.A.M. protects critical processes

For the safety upgrade, Pilz set up three safety zones. The entry zone, press cell and exit zone are each protected by safety fences and safety gates. The access points are protected by the I.A.M. system: anyone wishing to enter a zone authenticates themself on the access authorisation system PITreader card unit using their personal access card. COVRA also uses the digital maintenance safeguarding “Key-in-pocket” system: this prevents unauthorised persons gaining access to the application during maintenance. Once the maintenance work is complete, staff can also leave the safety zone by another door and sign out there. Safety light curtains PSENopt also protect the loading and unloading areas for the waste drums.

If a forklift interrupts the light beam, the roller conveyor switches off and restarts automatically when the forklift leaves the protected field. The easy-to-use safety concept protects the various zones from manipulation and unauthorised access.

Benefits

- Maintenance safeguarding Key-in-pocket system: the digital solution replaces mechanical keys and simplifies processes

- Sustainable integration of safety functions: much of the existing cabling continues to be used

- The safety controller PSS 4000 integrates seamlessly into the existing overall solution

Customer statement

After a risk analysis, we chose Pilz from a range of suppliers – the decisive factor was their ability to supply a complete package comprising mechanical fences, light curtains and safety controller. This complete solution was designed and implemented for us by Pilz.Willem Corbijn, Work Planner at COVRA

About COVRA

COVRA (Central Organisation for Radioactive Waste) is the only company in the Netherlands with permission to collect, process and store radioactive waste. Organisations such as hospitals, laboratories and nuclear power plants are obliged to dispose of their radioactive waste at COVRA. For this purpose, COVRA maintains a storage and processing plant at its site in the port area of Vlissingen-Oost.

Pilz’s products in the application

Access permission and operating mode selection

Here you will find potential applications – from simple authentication to complex access permissions, and access management through safe operating mode selection

Operating mode selection and access permission system PITmode

PITmode combines safety and security functions in one system. The devices enable functionally safe operating mode selection and the control of access permissions

Safety light curtains

With Pilz’s safety light curtains PSENopt and SPENopt II, you can protect your staff and capital goods – safely, efficiently, and economically

More Information

Related Story

Hydrogen: Safe Energy Carrier or Explosive Challenge?

Hydrogen is considered the energy carrier of the future. Its potential applications are diverse: it is used in industry when steelmaking, in the chemical or glass industry, for mobility as fuel for fuel cell vehicles or for electricity reconversion. The downside of the energy carrier: the gas is colourless and odourless, while at the same time highly flammable. Appropriate safety measures and safe monitoring systems are therefore required during production and handling.