How Motor Pole Count Influences Speed and Torque in Servo Motors

December 9, 2025

Servo motors deliver precise, repeatable motion, and their performance is shaped by how torque, speed, and stability interact under load. One structural element that defines this behavior is motor pole count.

Pole count determines how the magnetic field rotates inside the motor and how much torque the motor can produce at different speeds. Understanding this relationship supports better selection and sizing of servo motors for automation, robotics, and machine design.

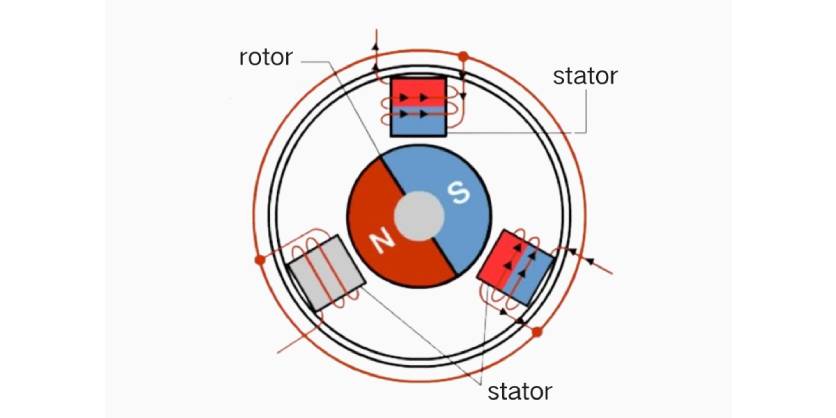

Pole count refers to the number of magnetic north and south poles created by the stator windings. These poles interact with the rotor magnets to generate torque. Fewer poles produce higher speeds, while more poles provide greater torque at lower speeds.

The servo drive controls current and position, but pole count defines the motor’s natural operating envelope.

How Motor Pole Count Shapes Servo Motor Speed

The motor’s achievable speed depends on how quickly the rotating magnetic field travels around the stator. Fewer poles allow the field to rotate faster, producing higher shaft RPM. Adding poles slows the electrical rotation, reducing maximum mechanical speed.

Low-pole servo motors support short indexing times, rapid acceleration, and high-cycle-rate motion. Higher-pole motors support more deliberate motion where force and smoothness matter more than speed.

How Motor Pole Count Influences Servo Motor Torque

Torque increases with pole count because the electromagnetic field interacts with the rotor more frequently per revolution. More poles provide more magnetic “engagement points,” allowing the motor to deliver stronger torque at lower speeds.

This behavior produces two clear families of servo motors:

- Low motor pole count: optimized for high RPM and fast acceleration

- High motor pole count: optimized for stronger shaft torque and stable low-speed operation

This tradeoff mirrors the principle described in your source document: increasing poles increases torque while decreasing speed.

The Speed–Torque Tradeoff in Servo Applications

Pole count determines whether a servo motor is inherently suited for fast motion or high-load capability.

- Low Motor Pole Count

- Higher top speed

- Faster acceleration

- Best for rapid indexing and light-load motion

- High Motor Pole Count

- Stronger torque

- Smoother low-speed control

- Better for presses, conveyors, lifts, and tensioning applications

Pole count is the baseline; the drive and feedback loop refine the motion inside those limits.

How Servo Drives Interact with Pole Count

The servo drive regulates current, commutation, and voltage. Pole count influences how demanding this task becomes.

- Low-pole motors require high electrical frequency to reach top RPM, increasing switching load on the drive.

- High-pole motors operate at lower electrical frequency and impose less switching demand.

- Drive limits often cap usable speed on low-pole motors before the mechanical limit is reached.

Pole count and drive capability must align to prevent overheating, instability, or control saturation.

Inertia Matching Considerations

Load-to-rotor inertia ratio is a major factor in servo performance. Pole count affects how much gearing is needed to balance the mechanical system.

- Low-pole motors often require higher gear ratios to boost torque and stabilize inertia relationships.

- High-pole motors can support heavier loads with lower ratios or direct coupling.

Correct inertia matching improves settling time, tuning stability, and motion quality.

Gearbox Selection Relative to Pole Count

Gear reducers are common in servo applications. Pole count influences which gear ratios make sense.

- Low-pole, high-speed motors typically require higher gear ratios to convert speed into torque.

- High-pole motors may operate effectively with lower ratios, increasing stiffness and reducing backlash.

- Some high-pole servo motors eliminate the need for gearing entirely in low-speed, high-torque tasks.

Matching pole count and gearing avoids oversizing the system and reduces complexity.

How Pole Count Influences Efficiency, Noise, and Vibration in Servo Motors

Pole count impacts not only torque and speed but also motor efficiency, acoustic noise, and vibration behavior—three factors that influence system performance, operator comfort, and long-term reliability.

Efficiency Effects

Efficiency depends on how effectively electrical energy is converted into mechanical output. Pole count affects this through copper losses, core losses, torque ripple, and commutation behavior.

Copper and Switching Losses

Low-pole motors require higher electrical frequency to reach top mechanical speeds.

- Low pole count → higher switching losses → reduced electrical efficiency

- High pole count → lower switching frequency → improved efficiency at low speeds

Iron Losses

Magnetic reversal frequency increases with speed.

- Low motor pole count at high speed increases hysteresis and eddy-current losses

- High motor pole count produces lower reversal frequency and reduced core losses at moderate speeds

Torque Ripple

Torque ripple causes micro-vibrations and energy waste.

- High-pole motors distribute torque more evenly

- Low-pole motors can exhibit more prominent ripple at low speed

Efficiency Profile by Use Case

- Low-pole motors are most efficient at medium-to-high speeds

- High-pole motors are most efficient in constant-torque, low-speed ranges

Noise Effects

Noise in servo motors comes from electromagnetic harmonics, aerodynamic components, and mechanical structure. Pole count influences electromagnetic noise significantly.

Harmonic Distribution

- Low pole count: fewer, higher-amplitude harmonics → sharper audible tones

- High pole count: more numerous, lower-amplitude harmonics → softer noise profile

Slot/Pole Interaction

Slot and pole combinations determine how magnetic forces align. High-pole motors generally reduce force concentration and lower tonal noise.

Commutation Frequency

High-speed commutation in low-pole motors may fall into the audible range. High-pole motors commutate at lower frequencies, reducing audible switching noise.

Vibration Effects

Vibration affects precision, accuracy, encoder feedback quality, and component wear. Pole count shapes the motor’s inherent vibration pattern.

Cogging Torque

- High-pole motors distribute magnetic forces more evenly, reducing cogging amplitude

- Low-pole motors may show larger cogging peaks at slow speeds

Radial Force Balance

High-pole motors spread magnetic forces over more locations, reducing bearing load variation.

Drive-Induced Vibration

High-pole motors require less aggressive current correction, lowering drive-induced mechanical vibration.

This combination makes high-pole servo motors well-suited for applications where low noise, precise motion, and minimal vibration are critical.

Where These Differences Matter in Real Applications

High-speed, low-pole servo applications:

- Pick-and-place robotics

- High-speed packaging

- CNC tool positioning

- Rapid indexing assemblies

High-torque, high-pole servo applications:

- Vertical load axes

- Conveyors and lifting systems

- Tensioning and winding

- Slow, controlled pressing or forming tasks

Matching pole count to load, speed range, and environmental expectations improves performance and reduces system cost.

Pole count defines the fundamental balance between speed and torque in a servo motor. Low-pole motors support rapid motion and high RPM, while high-pole motors deliver stronger torque and smoother low-speed control. Pole count also influences efficiency, noise, vibration, inertia matching, gearbox requirements, and drive behavior. When aligned correctly with application needs, these factors improve precision, reduce wear, and ensure stable, predictable motion across the full operating range.

Related Story

Tariff-Free Automation Products in Canada from Electromate

Electromate understands how recent tariff policies have impacted the cost and availability of automation components across North America. That is why the have made it easier for Canadian manufacturers, OEMs, and system integrators to source tariff-free mechatronic and robotic automation components.