Shaping Tomorrow: The Crucial Role of Early Exposure in Automation Careers

November 26, 2024

By Paul Aiello, Executive Director, Education, FANUC America

As someone deeply passionate about the field of robotics and automation, data from the 2024 Deloitte and The Manufacturing Institute Talent Study suggesting that half of the 3.8 million manufacturing jobs over the next decade could remain vacant keeps me awake at night.

It’s also the driving force behind so much of the effort that FANUC puts toward furthering robotics and CNC education, which can lead a student to a well-paying, skilled and sought-after role in as little as a year.

This fall, FANUC surveyed students at the Smartforce Student Summit during the International Manufacturing Technology Show (IMTS) to better understand the “aha!” moment that leads to a career in robotics, and the pitfalls that can sometimes prevent an interested student from pursuing further education.

The resulting study reveals key insights into the growing interest and challenges faced by students pursuing careers in this dynamic sector. It underscores the importance of early exposure, financial support, and the perception of automation careers among students.

High School Influence: Early Discovery of Automation Careers

Having spent over more than two decades at FANUC, I can attest to the impact of discovering automation early on. According to FANUC’s study, 40 percent of students discover their interest in automation careers while still in high school. This early exposure is crucial in shaping their career paths and fostering a long-term interest in the field.

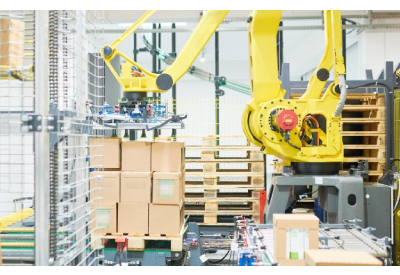

FANUC’s certified education efforts, which introduce students to robotics and provide industry-relevant training across more than 1,600 partner high schools, colleges and universities, play a pivotal role in this. The hands-on experience not only provides a basic understanding of robot operations and programming but also equips students with real-world solutions using the same products found in industrial workplaces. At completion of the program, students gain industry-recognized occupational certification.

Financial Support: Scholarships and Family Aid

The financial burden of education is a significant barrier for many aspiring automation professionals. FANUC’s study reveals that the majority of students—58 percent—rely on scholarships to fund their education. Notably, 12 percent of students indicated that their ability to continue their education hinges on the availability of scholarships. Additionally, 38 percent of students juggle jobs to afford their education, while 22 percent rely on family support for funding.

The FANUC Automation Endowed Scholarship Fund, launched in collaboration with the SME Education Foundation, is a game-changing scholarship that directly addresses these issues. As the largest automation scholarship in SME Education Foundation history, this initiative will foster the next generation of skilled professionals in advanced manufacturing and automation through a variety of education programs. Interested applicants can apply from November 1 – February 1.

Perception of Automation Careers: Innovative and Exciting

One of the most heartening findings from FANUC’s study is the perception of automation careers as innovative and exciting. Students selected these words as the most accurate descriptors of a career in automation, reflecting the dynamic and forward-thinking nature of the field. This positive perception is crucial for attracting and retaining talent in the industry. Given that manufacturers seek to fill 4 million high-skill, high-tech, and high-paying jobs over the next decade, this is indeed good news.

Programs like National Manufacturing Day, which bring high school students directly into manufacturing facilities to see, touch, and learn about real-world advanced technologies, are instrumental in fueling early exposure to automation. Opening the doors to students across FANUC America’s 25 locations, including the Rochester Hills, MI-based headquarters, is a priority for the company. This year, dozens of students were hosted in honor of Manufacturing Day, as part of FANUC’s ongoing commitment to provide community tours.

The positive reinforcement from influential adults in students’ lives also plays a significant role. When asked, 84 percent of students reported that the adults in their lives responded positively to their interest in a career in robotics and automation, further encouraging them to pursue their passion.

Industry and Education Partnership

Together, these three elements—early exposure to automation technologies, availability of financial support, and a shifting perspective on advanced manufacturing—are driving necessary change and growth in the sector. FANUC’s certified education program regularly travels the country, bringing together partner educational institutions and regional manufacturing businesses to discuss the importance of industry-relevant training, competency-based skills development and certifications.

With more than 25 million products installed worldwide, FANUC is the most common platform in automation. As an industry leader, FANUC understands the critical role of supporting the students, educators, and employers that will drive automation and Industry 4.0.

More Information

For more information on FANUC America’s initiatives and educational programs, visit FANUC America’s website.

Related Story

FANUC America Establishes $1M Scholarship Fund with SME Education Foundation to Elevate Advanced Manufacturing Skills

FANUC America, a global leader in industrial automation and robotics, proudly announces the establishment of the FANUC Automation Endowed Scholarship Fund in collaboration with the SME Education Foundation. As the largest automation scholarship in SME Education Foundation history, this initiative will foster the next generation of skilled professionals in advanced manufacturing and automation. The SME Education Foundation operates as the philanthropic arm of SME, the national nonprofit organization dedicated to the advancement of manufacturing.