Dynamics 365 Field Service Means Faster, Better Service

August 19, 2019

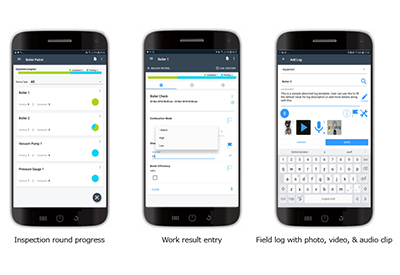

To simplify the service experience for customers and service professionals alike, Mazak Corporation has introduced Dynamics 365 (D365) Field Service, an electronic service management system. Designed to speed up the process and get your manufacturing equipment back up and running as fast as possible, D365 eliminates paper reports and manual follow-up calls in favor of an automated system made for easy, fast and effective communication.

With the new D365 system, manufacturers have access to a simple, powerful portal that provides up-to-date information 24 hours a day, seven days a week. In addition to a complete history of previous work orders and the status of current service requests, the system has digitized every step of the process. Now, electronic service invoices and receipts are sent automatically, while manufacturers can enter new service requests from any computer, tablet or smartphone. And at every step of the process – from the initial creation of a work order to the dispatch of field service engineers and the completion of the work – D365 sends email notifications to keep you up to date.

Set up in a fashion similar to the Mazak Parts Portal, the D365 portal offers unique login credentials for all the members of a manufacturer’s leadership team for the utmost in ease of use and accountability. Logging in provides a comprehensive dashboard that includes serial numbers assigned to a manufacturer’s location and real-time updates regarding current/open work orders. The system also knows what Mazak machines are present at your facility, which allows for quick generation of service requests, and can accommodate additional attachments to inform service engineers about the issue you’re facing. Users can even open their own cases.

On the Mazak side, the upgraded field service system will significantly improve the speed of our service. For example, thanks to a dynamic tracking system that maps issues, field service engineers will be able to conduct on-the-fly issue triage, while better overall data will improve the mean time-to-repair statistics. Plus, by eliminating the need for dozens of spreadsheets and forms, not to mention automated invoice and service report preparation, the entire service team will be able to increase its efficiency and reach customers faster.

The Dynamics 365 system will eventually expand to encompass all of Mazak Corporation, including accounting, parts ordering, sales administration, finance and operations. As with all Mazak technology, the company will also incorporate the system into its own manufacturing operations to improve quality and delivery times with better inventory control, superior build milestone tracking and robust MRP.