Understanding VFDs: The Technology Driving Smarter, More Efficient Systems

November 25, 2025

Variable Frequency Drives (VFDs) have become essential across modern industrial and commercial environments—but what makes them so valuable? A VFD, also known as an AC Drive or Inverter, is an electronic device that precisely controls the speed and torque of an AC motor. By adjusting the frequency and voltage supplied to the motor, a VFD delivers smooth acceleration, reduced inrush current, and efficient variable-speed operation. Whether you’re optimizing energy consumption or improving process control, the VFD is at the heart of smarter motor-driven systems.

How a VFD Works—The Essentials

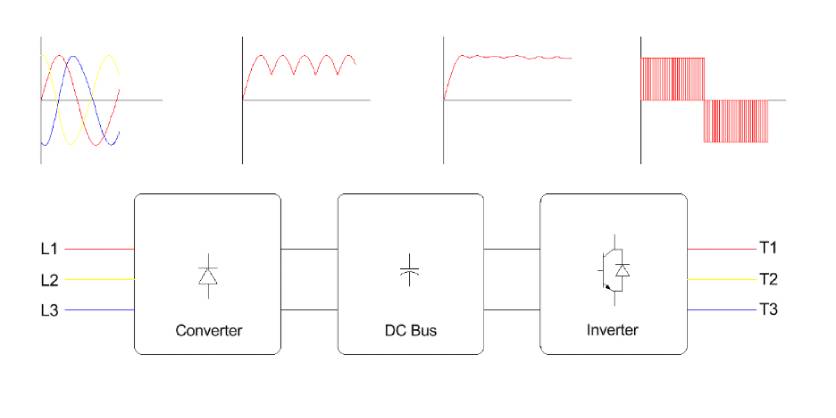

A VFD’s operation can be broken down into three core stages:

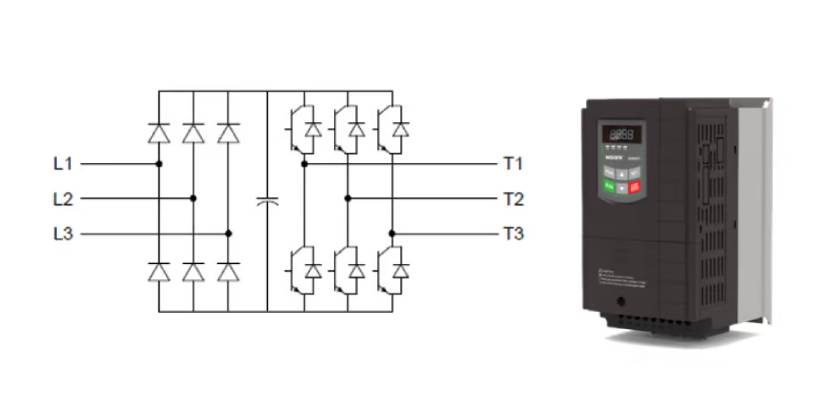

1. Converter: Incoming AC power is rectified into DC using diodes or thyristors.

2. DC Bus: A large capacitor smooths and stores this DC power, eliminating ripples.

3. Inverter: Insulated-Gate Bipolar Transistors (IGBTs) rapidly switch on and off to create a Pulse Width Modulated (PWM) output—essentially reconstructing AC power as a controlled, pseudo-sine wave.

In simple terms, a VFD converts AC → DC → AC, giving you full command over motor performance.

What’s Inside a VFD?

Beyond the power electronics, modern VFDs are packed with intelligence. Control circuits—microprocessors, I/O, communication interfaces, and onboard memory—manage everything from parameter changes to automation integration. Built-in power supplies deliver stable voltage for control boards, while extensive protection and sensing circuits guard against electrical and thermal faults. Cooling components such as heatsinks and variable-speed fans ensure long device life. And for users, HMIs and keypads make diagnostics easy and commissioning straightforward.

Introducing NOARK’s Ex9VF7 Series VFD

The NOARK Ex9VF7 series is engineered for precise control of AC motors—managing speed, torque, and direction effortlessly. Designed for pumps, fans, conveyors, and countless industrial processes, the Ex9VF7 improves energy efficiency and system performance across the board.

Power & Ratings

- 0.4kW–185kW (0.25HP–250HP)

- Input Voltage Options:

- 3-Phase 575VAC (+10%, −15%)

- 3-Phase 380–480VAC (+10%, −15%)

- 3-Phase 220–240VAC ±15%

- 1-Phase 220–240VAC ±15%

- 1-Phase 110–120VAC ±15%

- Rated Frequency:

- 50/60Hz

Key Features of the Ex9VF7

Designed with advanced DSP technology, the Ex9VF7 delivers high-precision motor control in a compact, installer-friendly form. Its flexible inverter control, high-resolution analog inputs, and fully mappable I/O channels make it easy to tailor the drive to any application.

The Ex9VF7 also incorporates:

- Automatic carrier wave adjustment for lower audible noise

- Automated torque profiling for strong low-speed performance

- Integrated EMC filters (C3 class) up to 150HP @480V and 25HP @600V

- Multi-protocol communication options: Standard Modbus, Optional BACnet & Ethernet/IP.

- Optional accessories including keypads, mounting kits, and more

Everything is engineered to support efficient installation, reliable performance, and seamless system integration—whether in a simple standalone setup or a complex automation network.

Where the Ex9VF7 Excels

Thanks to its versatility, durability, and intelligent controls, the Ex9VF7 is well-suited for a wide array of industrial and commercial uses, including:

- Carpentry plate hydraulic machines

- Sheet molding equipment

- Belt conveyors

- Ventilation systems

- Elevators and lift systems

- Steel production lines

- CNC machinery

- Packaging equipment

- Water and fluid pumps

Wherever motors play a critical role, VFDs help reduce energy usage, extend equipment life, and deliver precise, dependable performance.

Conclusion

VFDs are no longer optional—they’re a cornerstone of modern motor control. They reduce energy waste, improve operational efficiency, and provide the fine-tuned performance today’s applications demand. NOARK’s Ex9VF7 series brings all these advantages together in a robust, feature-rich package designed to serve your system for years to come.

If you’re planning your next motor-control upgrade, consider the Ex9VF7. Please click here you’re interested, and a member of our sales team will follow up shortly.

Please sign up for our VFD Webinar on Dec 10, to stay informed about new products, application tips, and industry updates.

More Information

Related Story

NOARK Launches Next-Gen Variable Frequency Drives

NOARK Electric, a global authority in motor control and power distribution solutions, unveiled its highly anticipated Ex9VF7 Variable Frequency Drives (VFDs) during the NECA 2025 tradeshow, taking place September 12–15 at Chicago’s McCormick Place West.