Saskatchewan Water Treatment Plant First in Canada to Use Progressive Design-Build Format

November 29, 2021

A planned major upgrade for south Saskatchewan’s Buffalo Pound Water Treatment Plant marks the first time in Canada that a progressive design-build format will be used in the construction of such a facility. “This format is more commonly used in the United States,” Buffalo Pound president and CEO Ryan Johnson points out. “Design-build presents inherent risks in terms of cost. Progressive design-build gives us more control over the outcome.” As he explains, progressive design-build is more of an integrative process where management sits down with the engineer and contractor to plan the project.

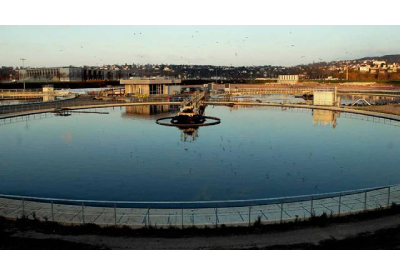

“There are some things management may know about the project that the engineer or contractor may not be aware of and not be taking into account,” Johnson notes. “By working together in this manner, we can better guarantee a fixed price.” The 100,000-square-foot Buffalo Pound Water Treatment Plant, serving Regina, Moose Jaw, and communities in-between, was first built in the mid-1950s. “We opened the plant in 1955 and expanded it in 1957,” Johnson reports. “We introduced new processes in 1985 and expanded again in 1989. We introduced a UV system in 2017 and new back-up generators over the last couple of years.

“When this project is completed, we shouldn’t have to do any more upgrades for at least 25 years.” The $222-million price tag for the renewal project is being funded jointly by all three levels of government. Johnson reports the design contract was awarded in June 2020 to Graham Infrastructure Inc. and Aecon Water Infrastructure Inc. and that the project will use primarily Saskatchewan tradespeople. Work on the project is expected to begin early next year.

The project is primarily renewal with some elements scheduled for demolition and replaced with construction. The plans call for new offices, a brand new ozonation process, new low lift pumps, a repurposing of the regeneration facility to a new chemical storage facility, clarifiers converted to dissolved air flotation, conversion of the granular activated carbon conduction to a biological process and some new processed waste lagoons with rehabilitation of existing lagoons. Johnson notes the overall size of the plant will remain about the same after completion of the project which is expected to be in 2025.

For more information, click here