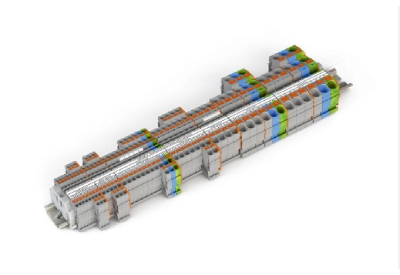

WAGO Rail-Mount Terminal Blocks with Levers, Push-Buttons Or Operating Slots

July 6, 2022

WAGO rail-mount terminal blocks are available in three different actuation variants: lever, push-button or operating slot – the right rail-mount terminal block for every application. The marking system and the multifunctional range of jumpers for the well-known WAGO TOPJOB® S Rail-Mount Terminal Blocks can also be used for the new rail-mount terminal blocks with levers.

Advantages:

- •Three actuation variants: lever, push-button, operating slot

- •Continuous Marking Possibilities

- •One existing range of TOPJOB® S jumpers for all three variants

- •Push-in connection technology: direct insertion of solid and fine-stranded conductors with ferrules for all variants

- •Test options for all variants

Rail-Mount Terminal Blocks with Levers

Connect without tools via rail-mount terminal blocks with levers. With the lever, opening and closing a clamping point by hand couldn’t be any easier. Especially when making connections in the field, the user benefits from the ease of handling offered by this intuitive design. The levers remain open for the simultaneous connection of difficult-to-bend conductors with large cross sections. Thanks to Push-in CAGE CLAMP®, solid and stranded conductors, as well as fine-stranded conductors with gas-tight, crimped ferrules, can also be connected by push-in termination.

Advantages:

- •Manual lever actuation – inherently clear, tool-free operation

- •Raising the lever opens the clamping point, freeing hands for quick and easy wiring.

- •The lever’s position clearly signals whether the clamping point is open or closed.

- •All conductor types can be connected and disconnected without tools.

- •Push-in CAGE CLAMP® terminates both solid and fine-stranded conductors with ferrules by simply pushing them into the unit.

- •Connection is secured when the easy-to-use lever is quickly and simply lowered into closed position.

To learn more about the Rail-Mount Terminal Blocks with Levers, click here

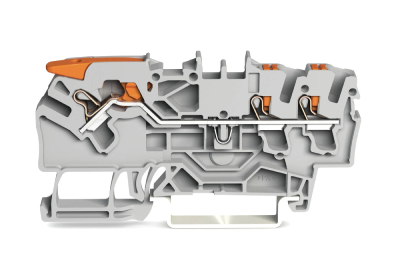

Rail-Mount Terminal Blocks with Push-Buttons

The TOPJOB® S Rail-Mount Terminal Block line also includes push-button variants. The rail-mount terminal blocks with push-buttons are available in the following nominal cross sections: 1.0 mm2, 1.5 mm2, 2.5 mm2, 4 mm2, 6 mm2, 10 mm2 and 16 mm2 (18, 16, 14, 12, 10, 8 and 6 AWG). They are available in two-, three- or even four-conductor variants. The clamping point is opened by actuating the push-button with any common tool. The orange push-button allows the actuator to be clearly and quickly distinguished from the conductor entry. The Push-in CAGE CLAMP® forms the heart of the TOPJOB® S Rail-Mount Terminal Blocks. It also offers the possibility of connecting solid and stranded conductors, as well as fine-stranded conductors with gas-tight, crimped ferrules, by simply pushing them in – no tools needed.

Advantages:

- •Use any common tool to open the clamping point via the push-button.

- •Intuitive operation – the orange color highlights the push-button.

To learn more about the Rail-Mount Terminal Blocks with Push-Buttons, click here

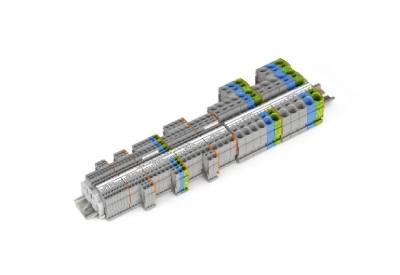

Rail-Mount Terminal Blocks with Operating Slots

The TOPJOB® S Rail-Mount Terminal Blocks with operating slots enable easy connection with an operating tool. The operating tool, which is used for connecting fine-stranded conductors, remains in the operating slot until termination is complete. The clamping point is held open, keeping hands free for wiring. The rail-mount terminal blocks with operating slots feature a wide and flexible product range. In addition to single-deck terminal blocks with a large cross section range of 0.14 mm2 to 25 mm2 (24–4 AWG), double- and triple-deck terminal blocks, along with function blocks, are also available for any type of application.

Advantages:

- •The operating tool remains in the slot until termination is complete.

- •The clamping point is marked by the inserted operating tool.

- •The conductor entry is held open, keeping hands free for wiring.

To learn more about the Rail-Mount Terminal Blocks with Operating Slots, click here

To learn more about this family of WAGO Rail-Mount Terminal Blocks with Levers, Push-Buttons Or Operating Slots, click here