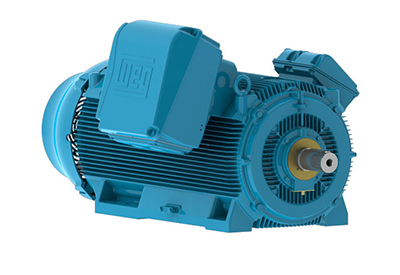

Pamensky: HGF Low Voltage Machines

February 3, 2021

The HGF line is differentiated by its high performance combined with low maintenance costs. This product line is ideal for operating in the toughest applications, which require increased strength and durability of motors. The HGF motors are being designed according to the highest technological standards available in the market, using modern computer software for mechanical, electrical and thermal analysis evidenced by performing rigid tests and checks. The result of this innovative development is a flexible product, suitable to the requirements of international standards and fully aligned with world market trends. This states WEG commitment not only with customers but also with the environment, bringing global solutions more and more optimized for its products and processes.

Standard Features

- – Sinusoidal power supply up to 690V

- – Motors manufactured in 2 to 12 poles

- – Cast iron frame 5000 to 9600

- – Internal and external self-ventilated enclosed cooling system

- – Service Factor: 1.0

- – Class of insulation: F

- – Temperature rise: 80°C

- – Ambient temperature: 40°C

- – Altitude: 1000 m

- – Mounting: F1 or F2

- – Starting method: DOL

- – Degree of Protection: IP55

- – Service duty: (S1)

- – Temperature detector: Pt100

- – 2 per phase with 3 wires

- – 1 per bearing with 3 wires

- – 06 loose connection leads inside the terminal box (without terminal block)

- – Labyrinth tachonite in grease lubricated bearings

- – Grease lubricated bearings for the following frame sizes:

- – For 2 pole motors in the following frame sizes:

- – Up to frame 6800 (inclusive) for 60 Hz;

- – Up to frame 7000 (inclusive) for 50 Hz;

- – For 4 pole motors in the following frame sizes:

- – Up to frame 9600 (inclusive) for 60 and 50 Hz;

- – Grease lubricated bearings for 6 pole motors and above;

- – Sleeve bearings for the following frame sizes:

- – For 2 pole motors:

- – Frame 7000 and above for 60 Hz;

- – Frame 8000 and above for 50 Hz;

- – For 4 pole motors in frame 9600.

- – Electrically insulated non-drive end bearing for frames 6800 and above, when connected directly to the power supply

- – Paint: RAL 5009 – Blue – Acrylic polyurethane Polyamide epoxy

- – Two accessory terminal boxes, one for signal accessories and the other for those accessories requiring power supply (space heaters)

- – Single phase space heater

- – Stainless steel nameplate

- – Grounding lug on the frame and terminal box

Optional Features

- – Service Factor: 1.15

- – Insulation Class: H

- – Temperature rise: 105°K for class F, 125°K for class H

- – Ambient temperature above 40°C

- – Altitude above 1000 m

- – Degree of Protection IPW55 and above

- – Special balance

- – Base: rail, sliding base, extended feet, rebuilt feet, anchorage plate

- – Steel welded t-box in different sizes

- – Power factor correction capacitors

- – Non-reversion ratchet

- – Centrifugal switch

- – Pt100, Thermistor (PTC or NTC), Thermostat (Bimetallic)

- – Two energized power terminal boxes

- – Shaft: Special dimensions, double shaft end, tapered, hollow, special steel

- – Encoder

- – Sleeve bearing

- – Oil lubricated bearing

- – Special bearing (overdesigned) for axial or radial thrust

- – Special painting

- – Terminal block

- – Cable gland in the terminal box entrance

- – Protection against voltage surge

- – Aluminum, copper or brass rotor

- – Vibration detector

- – Noise suppressor in the air inlet and outlet

- – Tachogenerator

- – CT for differential and integral protection

- – Bearing thermometer with gauge with/without contacts

- – Signal transducer

- – One or more accessory terminal boxes

- – Indep. hydraulic oil circulation sytem for sleeve bearing

- – Electrically insulated non-drive end bearing for all frame sizes when driven by frequency drive

- – Both bearings are electrically insulated

- – Grounding brush on drive end bearing for all frames when driven by frequency converter (except for classified area)

- – Independent cooling

- – Inpro Seal

- – VFD Duty

H Line Machines are also available with:

- – Class 1 Division 2

- – API 541