New: IO-Link Safety from Pilz

April 25, 2024

Communicate safely at field level – in one system

IO-Link Safety satisfies the wish for flexible automation. How, you ask? It’s quite simple: with the safe, standardised point-to-point communication IO-Link Safety, you can integrate sensors up to field level – quickly and conveniently. At the same time, IO-Link Safety offers new possibilities for data diagnostics, thus helping to optimise your processes.

- Safe point-to-point communication from the controller to the sensor in the field

- Standardised worldwide in IEC 61139-2

- Maximum safety up to PL e of EN ISO 13849-1 (SIL 3 of IEC 61508/62061)

- Fieldbus-independent

Benefit from Pilz’s expertise as a significant partner and developer of the IO-Link Safety standard. Pilz offers you the complete system with master and sensors, and supports you with the integration of IO-Link Safety into your application!

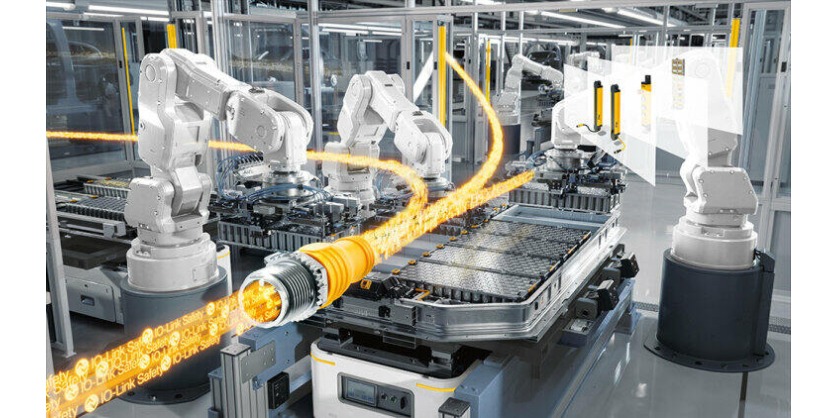

IO-Link Safety with Pilz – a first impression

IO-Link Safety: Flexible. Simple. Intelligent.

Increase your productivity

IO-Link Safety devices are identified automatically and parameters are adopted directly. This makes it easier to swap components and reduces machine downtimes caused by repairs. At the same time, fewer device types are needed, thus reducing complexity in purchasing and creating space in the warehouse.

Save time

The point-to-point connection simplifies the sensor wiring in the field considerably. You connect the 3-core unshielded cable directly to the IO-Link Safety Master. To do this, IO-Link Safety uses standard industrial connectors. The devices are configured either via PLC parameter settings or using the Pilz configuration tool. This makes installation and commissioning significantly easier.

Optimise your processes

IO-Link Safety creates new possibilities for data diagnostics, with the self diagnostic function for improved maintenance, for example. The field device delivers any data that is relevant to the status of the machines directly to the controller. From there it can be used to optimise processes.

How to implement IO-Link Safety

Are you using a large number of safety sensors in your plants? Then IO-Link Safety is the right solution for you. This extension of the IO-Link technology enables safe, seamless communication from the controller to the safety-related sensors. Simple field integration with rapid wiring and data diagnostic options offer huge potential to implement your automation both flexibly and productively.

Packaging plant with access guarding

- Requirement:

Save time and space when integrating the safety sensors.

- Solution:

Decentralised IO-Link Safety Master PDP 67 IOLS for the integration of safety light curtains PSENopt II Advanced IOLS and safety gate guarding. The E-STOP and the IO-Link signal lights are also connected to the IOLS Master.

- Benefits:

Space-saving integration via decentralised Master in the field, plus simplified wiring Considerable time saving during installation.

Material handling with integrated robotics

- Requirement:

Safeguarding of access points and safety gates, plus a minimising of machine downtimes.

- Solution:

Safety light curtains with muting function and the control unit PITgatebox IOLS are integrated via the Pilz IO-Link Safety Master. This serves as the “IO-Link Safety hub” for the safety locking device PSENmlock.

- Benefits:

Simple, time-saving integration of the safety sensors, plus intelligent data diagnostics for predictive maintenance.

The Pilz IO-Link Safety System

To integrate IO-Link Safety you need a Master, field devices such as safety sensors and the right cable and configuration tool. Pilz offers the complete one-stop system – safe and reliable.

IO-Link Safety Master

As the interface to the safety controller, the IO-Link Safety Master enables point-to-point communication up to field level. With the Pilz Master PDP 67 IOLS, you can also connect IO-Link sensors and classic safety sensors alongside the IO-Link Safety devices.

IO-Link Safety devices

IO-Link Safety devices communicate directly with the IO-Link Safety Master and provide important status information. With the safety light curtains PSENopt II Advanced IOLS, Pilz offers the first IO-Link Safety device for access guarding. The control unit PITgatebox IOLS can be used in conjunction with the safety locking device PSENmlock for safety gate guarding.

Cable and configuration tool

IO-Link Safety uses 3-core, unshielded standard cable. Up to 32 Bytes of data are transmitted in two directions with IO-Link Safety, at up to 230.4 kbit/s. You will find this cable in the right lengths for your application in the Pilz portfolio. With the Pilz configuration tool you can configure and set parameters for the IO-Link Safety Master and devices.

Find out more about IO-Link Safety now!

Need further information or still have questions?

Pilz is there for you in person to answer any questions you might have about IO-Link Safety.

Relates Story

Gold for Pilz Safety Locking Devices: PSENslock 2 and PSENmlock Mini are “Product of the Year”

Each year, readers of the industry journal Computer&Automation vote for their favourite products from the wide range of product releases published within the year. There are various selection categories. Pilz’s two new safety locking devices PSENslock 2 and PSENmlock mini were voted in 1st place in the Safety & Security category. They are absolutely delighted about the readers’ vote and thank you for your support!