New HPS Titan X Encapsulated Transformer

December 17, 2021

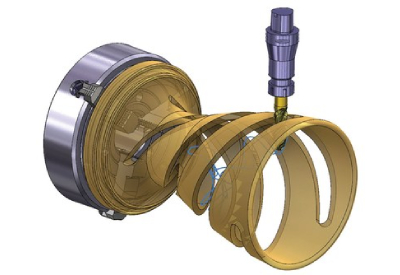

HPS Titan™ X encapsulated transformers are designed for industrial and hazardous applications requiring conformity to IECEx; complimenting our existing HPS Titan N product. The transformer core and coil is completely encapsulated in epoxy and silica, providing excellent protection from airborne contaminants and prevents the ingress of moisture. The removable hinged door and factory installed grounding lugs, reduce installation time and money.

-

- •Certified for IECEx, ATEX and UKEx

-

- •Fully certified for use in most of the World’s hazardous locations

-

- •Ratings from 6 to 75 kVA

-

- •Three Phase

-

- •Temperature Rise 115C, 80C at 180C Insulation Class

Advantages of IECEx Certification

There is an increasing need for installation efficiency and safety in industrial automation and hazardous locations. Electrical equipment and their use in these areas are often covered by a wide range of IEC standards and is highly regulated.

The use of the IECEx Conformity Assessment System and its Schemes provides clear advantages for industry and governments. Read more on IECEx Certification here

Encapsulated Transformers for Harsh Environments – 3ph Current: HPS Titan™ Series

HPS Titan™ Series encapsulated transformers offer an innovative design with technological improvements for industrial and hazardous applications. The transformer core and coil is completely encapsulated in epoxy and silica, providing excellent protection from airborne contaminants and prevents the ingress of moisture. The three phase design has a removable hinged door and factory installed grounding lugs, reducing installation time and money.

HPS Titan Series is available in two lines:

HPS Titan N:

cULus Listed – approved for applications requiring UL and/or CSA certifications

HPS Titan X:

IECEx, ATEX, UKEx Certified – approved for applications requiring IEC conformity

HPS Titan™ N

- ANSI/ISA 12.12.10 – File No. E258346 (Class 1, Division 2, Groups A, B, C, D and Class I, Zone 2, Group IIC, T3 Hazardous Locations) – T3C/T3A Temperature Classification

- 10kV BIL

- Copper with an electrostatic shield on all units

- 60 Hz (50/60Hz available)

- Ratings from 2 to 150 kVA three phase

- Temperature Rise 115°C, 95°C, 80°C at 180°C insulation class

- cULus Listed

- OSHPD Certified

- ABS type approval for Marine Duty

- Suitable for 50°C ambient while maintaining T3C/T3A Temperature Classification

HPS Titan™ X

- IEC 60079-0, IEC 60079-7,5.1 – Hazardous Locations Class I, Zone 2, Group IIC, T3

- 10kV BIL

- Copper with an electrostatic shield on all units

- 60 Hz and/or 50/60 Hz

- Ratings from 6 to 75kVA three phase

- Temperature Rise 115°C, 80°C at 180°C insulation class

- IECEx, ATEX & UKEx Certified

- OSHPD Certified

- ABS type approval for Marine Duty

- Rated ambient temperature range (°C) -25°C to +40°C

- Standard Glass Filled Naylon Condensate Valve

For more information, click here