COMING SOON! Upgraded EtherNet/IP Interface for POSITAL Encoders

December 3, 2021

The updated EthernNet/IP communications interface helps optimize data transfer therefore minimizing downtime due to transmission delays. This improved protocol not only has advanced network management tools, it also supports a communications cap which allows installers to define the device’s IP address through a set of three rotary switches. High temperature warnings, monitored acceleration levels, and a time counter can all now be accessed through this upgrade. POSITAL’s implementation of this upgrade meets all requirements of the ODVA’s conformance testing.

More about EtherNet/IP

- Advanced Network Management Tools

- Simplified System’s Setup

- New Device Monitoring Capabilities

- Optimized Data Transmission

Ethernet/IP was developed by ControlNet International (CI), the Industrial Ethernet Association (IEA) and the Open DeviceNet Vendor Association (ODVA) to be a common application-layer protocol for control systems based on Ethernet technology. Like ControlNet and DeviceNet; it is based on the CIP protocol that has become a widely accepted standard, e.g. in the automobile industry. For hard real-time applications the extended protocol CIP sync was specified. Ethernet/IP is a pure software based solution that does not require any specific ASICS. Detailed information is available under www.odva.org

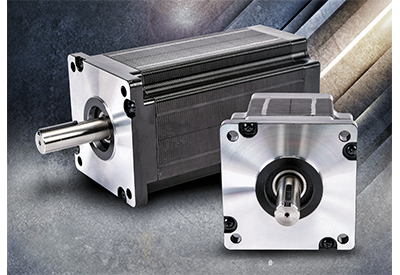

EtherNet IP Rotary Encoder

The POSITAL provides Ethernet IP encoder as single-turn or multi-turn variant up to a resolution of 16 bit per revolution. The Ethernet / IP encoders are ideally suited for factory automation because many mechanical characteristics, as well as connector and cable outlets are available. In addition also Ex protected variants are available. The encoders can be perfectly adapted by various parameters setting to the individual requirements.

For more information about POSITAL’s EtherNet/IP upgrade, click here