Good Luck! – Safety for Underground Mining by PILZ

May 12, 2022

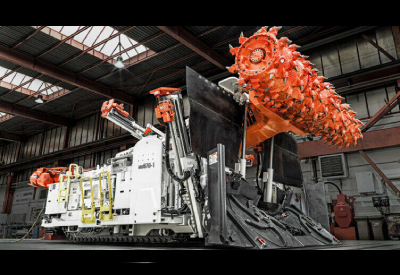

The safety requirements for mining machines are high; a long and complex process ensues before the machine is ready for use. To meet all the necessary safety specifications, the technology “behind it” must be programmed, tested and then installed on the machine.

As Pilz was a long-standing and experienced development partner, Sandvik also had them on board for the Sandvik MB670-1 Bolter Miner, which is used in longwall coal mining. The ambitious goal of the Austrian mining machine manufacturer is to guarantee reliable explosion protection, among other things.

The solution: today, the automation system PSS 4000 provides safe nozzle monitoring SMS III on the Bolter Miner – and the safe small controller PNOZmulti 2 performs safety functions such as emergency stop.

Explosion risk safely under control

To completely exclude a potential hazard, it is essential to comply with the prescribed minimum values for water flow, water pressure and air pressure when the nozzles are used. The automation system PSS 4000 now takes the place of the previous system in monitoring the nozzles and the machine – with an optimized function range.

As a result, if any nozzles are blocked or lost, for example, this can be detected safely. Depending on the machine, PSS 4000 also offers Sandvik the opportunity to adapt the parameter settings again, or if necessary, the end user can do this himself – within the scope of parameters enabled by Sandvik.

Another benefit: each machine can be produced in series, as the solution can be used on various machine types. So the new nozzle monitoring system with PSS 4000 hits the mark as regards operability and operational safety – for total safety underground.

The benefits at a glance:

- •Customized Sandvik machines: parameter settings are now readily adaptable

- •State-of-the-art safety solution with PSS 4000 can be used on a variety of Sandvik’s machine types and now enables series production

- •Today, the automation system PSS 4000 enables the nozzles to be fully monitored

Customer statement

“As Pilz is the expert in safety technology and has experience of approval processes with the authorities, we decided to work with Pilz to implement the project “Nozzle monitoring SMS III”.”

Dominik Pichler, Manager Final Assembly Electric & Electronic Centre of the Mechanical Cutting Division at Sandvik