NVIDIA 800 VDC Architecture Will Power the Next Generation of AI Factories

November 4, 2025

By Mathias Blake, Martin Hsu, Ivan Goldwasser, Harry Petty and Jared Huntington

The exponential growth of AI workloads is increasing data centre power demands. Traditional 54 V in-rack power distribution, designed for kilowatt (KW)-scale racks, isn’t designed to support the megawatt (MW)-scale racks coming soon to modern AI factories.

NVIDIA is leading the transition to 800 VDC data centre power infrastructure to support 1 MW IT racks and beyond, starting in 2027. To accelerate adoption, NVIDIA is collaborating with key industry partners across the data centre electrical ecosystem, including:

- Silicon providers: Analog Devices, Infineon, Innoscience, MPS, Navitas, OnSemi, Renesas, ROHM, STMicroelectronics, Texas Instruments

- Power system components: Delta, Flex Power, Lead Wealth, LiteOn, Megmeet

- Data centre power systems: Eaton, Schneider Electric, Vertiv

This initiative will drive innovations that aim to establish high-efficiency, scalable power delivery for next-generation AI workloads, to ensure greater reliability and reduced infrastructure complexity.

The limits of legacy rack power systems

Today’s racks in AI factories rely on 54 VDC power distribution, where bulky copper busbars shuttle electricity from rack-mounted power shelves to compute trays. As racks exceed 200 kilowatts, this approach begins to hit physical limits:

- Space constraints: Today’s NVIDIA GB200 NVL72 or NVIDIA GB300 NVL72 feature up to eight power shelves to power the MGX compute and switch shelves. Using the same 54 VDC power distribution would mean power shelves would consume up to 64 U of rack space for Kyber at MW scale, leaving no room for compute. At GTC 2025, NVIDIA exhibited an 800 V sidecar to power 576 of the Rubin Ultra GPUs in a single Kyber rack. The alternative approach is to use a dedicated rack of power supplies for every compute rack.

- Copper overload: The physics of using 54 VDC in a single 1 MW rack requires up to 200 kg of copper busbar. The rack busbars alone in a single 1 gigawatt (GW) data centre could require up to half a million tons of copper. Clearly current power distribution technology isn’t sustainable in a GW data centre future.

- Inefficient conversions: Repeated AC/DC transformations across the power chain are not energy efficient and increase failure points.

The 800 VDC revolution

NVIDIA 800 VDC architecture addresses these challenges through a holistic redesign. NVIDIA is collaborating with the data centre power ecosystem on the innovations and changes that will be necessary to realize this concept.

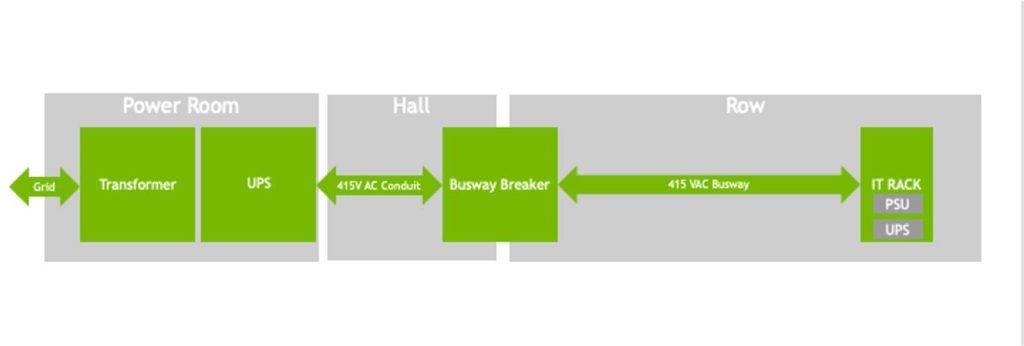

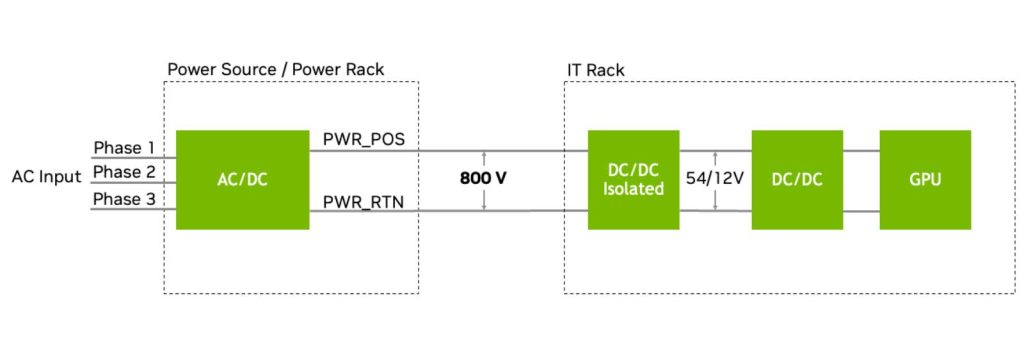

Grid to power room

Traditional power distribution for data centres involves multiple voltage conversions, which can introduce inefficiencies and increase the complexity of the electrical system. By converting 13.8 kV AC grid power directly to 800 VDC at the data centre perimeter using industrial-grade rectifiers, most intermediate conversion steps are eliminated. This streamlined approach minimizes energy losses, which typically occur during multiple AC/DC and DC/DC transformations.

This approach also significantly reduces the number of power supply units (PSUs) with fans needed in the power chain. Fewer PSUs and fans leads to higher system reliability, lower heat dissipation, and improved energy efficiency, making VDC distribution a more effective solution for modern data centres and significantly reducing total component count.

With a single-step AC/DC conversion, the system benefits from a more direct and efficient power flow, reducing electrical complexity and maintenance needs. Innovations will still be required to fully deliver possible overcurrent protection reliability and maintenance gains. VDC also lowers transmission losses and offers better voltage stability, ensuring consistent power delivery to critical infrastructure while reducing copper and overall material costs. This design can enhance operational efficiency while simplifying data centre power architecture.

Row-level power management

Using 800 V busways and switching from 415 VAC to 800 VDC in electrical distribution enables 85% more power to be transmitted through the same conductor size. This happens because higher voltage reduces current demand, lowering resistive losses and making power transfer more efficient.

With lower current, thinner conductors can handle the same load, reducing copper requirements by 45%. Additionally, DC systems eliminate AC-specific inefficiencies, such as skin effect and reactive power losses, further improving efficiency. By adopting 800 VDC distribution, facilities gain higher power capacity, better energy efficiency, and lower material costs.

IT rack implementation

By adopting direct 800 V input, compute racks can efficiently handle power delivery without relying on integrated AC/DC conversion stages. These racks accept two conductor 800 V feeds, and utilize DC/DC conversion in the compute rack to drive the GPU devices. Eliminating rack-level AC/DC conversion elements frees up valuable space for more compute resources, allowing for higher-density configurations and improved cooling efficiency. Compared to traditional AC/DC conversion, which requires additional power modules, direct 800 V input simplifies the design while enhancing performance.

Key benefits of 800 VDC

Scalability: Supports racks ranging from 100 kW to over 1 MW using the same data centre power infrastructure, allowing seamless expansion.

Efficiency: Improves end-to-end efficiency by up to 5% compared to current 54 V systems, ensuring better energy utilization.

Copper Reduction: Compared to traditional 415 VAC or 480 VDC architectures, 800 VDC enables significant reductions in current, copper usage, and thermal losses across the data centre backbone.

Reliability: Traditional IT rack PSUs depend on overprovisioning to reduce downtime, but this leads to frequent maintenance cycles to replace failed modules. While centralizing power conversion improves system reliability, fault detection and serviceability in VDC systems is a key area for innovation.

Space constraints in IT rack PSUs contribute to thermal challenges, creating tradeoffs between cost and long-term reliability. Shifting power conversion out of the rack mitigates these risks.

Future-proofing: Designed to meet the requirements of 1 MW racks, with the ability to scale efficiently to even higher-power racks as data centre demands evolve.

Addressing the challenges of facility-level VDC

While higher-voltage DC architectures have been piloted in the past, widespread adoption was limited by technical and deployment challenges. Today, the convergence of AI-driven rack densities, advances in power conversion, and the industrial base built around EV charging standards is changing the equation.

Deploying 800 VDC at the facility level introduces new challenges in safety, standards, and workforce training. NVIDIA and its partners are actively studying the CapEx and, OpEx, and safety implications of both traditional transformer-based and solid-state transformer (SST) approaches to enable this transition.

The path forward

800 VDC isn’t just about today’s racks—it’s about future-proofing AI infrastructure. Full-scale production of 800 VDC data centres will coincide with NVIDIA Kyber rack-scale systems in 2027, ensuring seamless scalability for increasingly demanding AI models.

Energy storage solutions to help data centre infrastructure handle load spikes, and subsecond scale GPU power fluctuations, is part of the 800 VDC architecture. Stay tuned for more details.

As AI workloads require 100x to 1,000x more compute per query, this architecture enables sustainable growth while cutting total cost of ownership (TCO) by up to 30% through gains in efficiency, reliability, and system architecture improvements.

Key efficiency gains

- Up to 5% improvement in end-to-end power efficiency

- Maintenance costs reduced by up to 70% due to fewer PSU failures and lower labor costs for component upkeep

- Lower cooling expenses from eliminating AC/DC PSUs inside IT racks

NVIDIA is not just building faster GPUs, but reengineering the entire power stack to unlock the full potential of AI. The age of hyperefficient, MW-scale AI factories begins now.

Updated on July 31 to add new silicon partners and clarify the power branding.

More Information

You can also watch the recent Data Center World 2025 session, Data Centers as Scale in the Age of Accelerated Computing.

Related Story

US Technology Leaders Tap NVIDIA AI Software to Transform World’s Industries

NVIDIA has announced it is teaming with U.S. technology leaders to help organizations create custom AI applications and transform the world’s industries using the latest NVIDIA NIM™ Agent Blueprints and NVIDIA NeMo™ and NVIDIA NIM microservices.

Across industries, technology organizations like AT&T, Lowe’s and the University of Florida are using the microservices to create their own data-driven AI flywheels to power custom generative AI applications.

U.S. technology consulting leaders Accenture, Deloitte, Quantiphi and SoftServe are adopting NVIDIA NIM Agent Blueprints and NVIDIA NeMo and NIM microservices to help clients in healthcare, manufacturing, telecommunications, financial services and retail create custom generative AI agents and copilots.

Data and AI platform leaders Cadence, Cloudera, DataStax, Google Cloud, NetApp, SAP, ServiceNow and Teradata are advancing their data and AI platforms with NVIDIA NIM.